Electronic Manufacturing Services: A Comprehensive Guide

In today’s rapidly evolving manufacturing landscape, Electronic Manufacturing Services (EMS) have become essential for companies seeking to optimize their production processes and maintain competitive advantage. Let’s explore how these services transform the electronics industry and why they matter for businesses across various sectors.

Understanding Electronic Manufacturing Services

Electronic Manufacturing Services represent a comprehensive suite of specialized services offered by companies dedicated to electronic component and assembly production. These services span from initial design and prototyping to full-scale production, testing, and distribution. Through EMS partnerships, Original Equipment Manufacturers (OEMs) can streamline operations, reduce costs, and enhance product quality.

The EMS industry has evolved beyond simple contract manufacturing to become a strategic partner for OEMs worldwide. Modern EMS providers deliver value-added engineering and manufacturing outsourcing, enabling OEMs to focus on core competencies like research, development, marketing, and customer relationships.

What are Electronic Manufacturing Services?

EMS providers offer a comprehensive range of specialized manufacturing and engineering support services. Their core offerings include:

- Design assistance and optimization

- Component procurement and supply chain management

- Printed circuit board assembly

- Product testing and quality assurance

- Logistics management and distribution

- Repair and return services

The Role of EMS in Various Industries

| Industry | EMS Applications |

|---|---|

| Consumer Electronics | Smartphones, computers, home entertainment systems |

| Automotive | Infotainment systems, driver assistance components |

| Medical Devices | Life-critical equipment with strict regulatory compliance |

| Aerospace & Defense | Specialized electronic systems meeting military specifications |

| Telecommunications | Infrastructure equipment, networking devices |

Benefits of Outsourcing to EMS Providers

Outsourcing to EMS providers offers strategic advantages beyond operational cost reduction. Companies gain access to advanced manufacturing capabilities, technical expertise, and optimized supply chain networks that would be costly to develop internally.

Cost Reduction and Efficiency

EMS partnerships deliver substantial financial benefits through:

- Economies of scale in component purchasing

- Reduced capital expenditure requirements

- Optimized manufacturing efficiency

- Flexible production scaling

- Minimized waste and overhead costs

Faster Time to Market

EMS providers accelerate product development through specialized knowledge and ready-to-deploy production systems. Their established frameworks and regulatory expertise enable rapid transitions from prototype to full production, potentially reducing development timelines by months while maintaining quality and compliance standards.

Improved Productivity and Focus

Outsourcing manufacturing operations to EMS providers enables companies to concentrate on their distinctive strengths and core business functions. By delegating production responsibilities to specialized partners, organizations can redirect internal resources toward activities that drive competitive advantage, such as product innovation, brand development, and customer relationship management. This strategic realignment consistently delivers substantial productivity improvements, allowing teams to apply their expertise where they create maximum value.

EMS providers offer comprehensive production capabilities that go well beyond basic assembly. Their systems integration services, known as ‘box build’ services, encompass:

- Printed circuit board assemblies

- Wire harness integration

- Enclosure fabrication

- Comprehensive testing protocols

- Complete functional system assembly

Challenges in the EMS Industry

The Electronic Manufacturing Services industry confronts several complex challenges affecting operational efficiency and sustainability. Supply chain vulnerabilities have become particularly evident, with component shortages, delivery delays, and semiconductor price fluctuations creating significant production bottlenecks. These issues, intensified by global events like pandemics and geopolitical tensions, have necessitated a fundamental reassessment of operational strategies.

Rising Labor Costs and Automation

Labor expenses present an escalating challenge for EMS providers globally, with traditional manufacturing hubs experiencing substantial wage increases. In some Asian regions, labor costs have risen by 10-15% annually, significantly impacting competitive pricing structures. This trend has accelerated the industry’s shift toward automation solutions.

| Automation Solution | Benefits |

|---|---|

| Collaborative robots | Enhanced human-machine cooperation, improved efficiency |

| Automated optical inspection | Superior quality control, reduced errors |

| Autonomous guided vehicles | Streamlined material handling, reduced labor requirements |

Global Competition and Market Dynamics

The EMS marketplace has evolved into a highly competitive global arena with distinct regional specializations:

- China – High-volume production efficiency

- Southeast Asia – Balanced cost structures

- Eastern Europe – Proximity to European markets

- North America – High-complexity, regulated product manufacturing

E-Waste Management and Environmental Concerns

With approximately 53.6 million metric tons of electronic waste generated annually, EMS providers must implement comprehensive lifecycle management strategies. Regulatory frameworks like WEEE and RoHS have established strict compliance requirements affecting all aspects of manufacturing.

- Circular economy design approaches

- Energy-efficient manufacturing processes

- Product take-back programs

- Biodegradable materials implementation

- Lead-free solder adoption

- Recyclable packaging solutions

Future Trends in Electronic Manufacturing Services

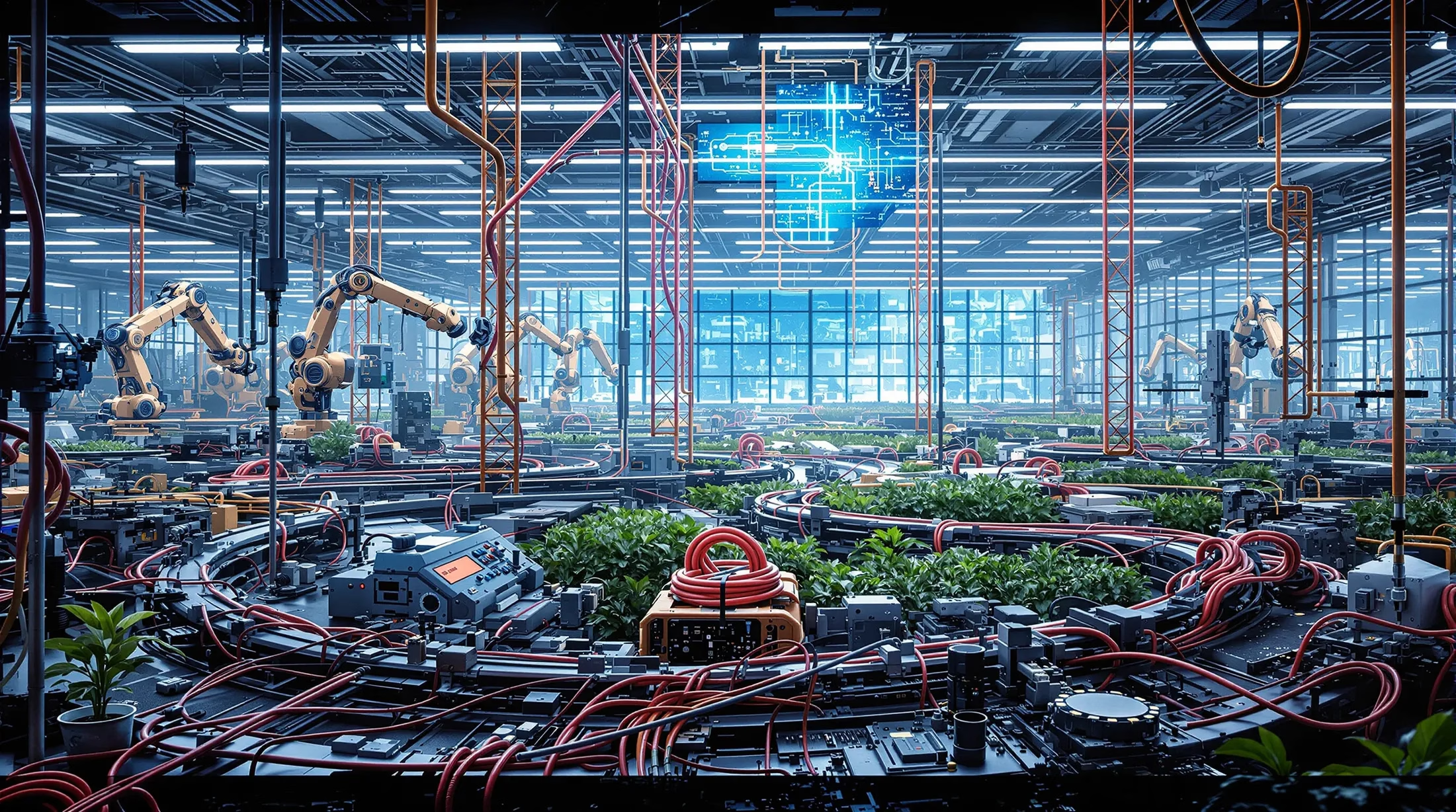

The electronic manufacturing services (EMS) industry is undergoing a profound transformation driven by technological advancements, evolving customer demands, and environmental consciousness. These emerging trends are fundamentally reshaping electronics production, creating new opportunities while challenging traditional manufacturing approaches. The next generation of EMS will be defined by intelligent systems, sustainable practices, and unprecedented customization capabilities.

Several key developments are revolutionizing the industry landscape. The integration of advanced automation and artificial intelligence is dramatically improving production efficiency and precision. Simultaneously, environmental concerns and stricter regulations are accelerating the development of eco-friendly manufacturing processes and energy-efficient devices, creating a more sustainable and technologically sophisticated EMS ecosystem.

Increased Automation and AI Integration

Advanced robotics, machine learning algorithms, and AI systems are revolutionizing electronic manufacturing. Modern facilities utilize collaborative robots for precise component placement and AI-powered inspection systems that detect microscopic defects. This intelligent automation enhances manufacturing capabilities, enabling the production of complex devices with exceptional accuracy.

- Smart factories with interconnected IIoT networks

- Real-time production data analysis

- Predictive maintenance systems

- Self-optimizing manufacturing environments

- 35-40% improvement in production efficiency

- Up to 65% reduction in quality issues

Development of Energy-Efficient and Eco-Friendly Devices

Sustainability has become a cornerstone of modern electronic manufacturing, driven by consumer demand and regulatory requirements. Leading EMS providers are implementing innovative solutions that deliver both environmental benefits and operational cost savings.

| Sustainability Initiative | Impact |

|---|---|

| Smart building systems | 30-40% reduction in energy usage |

| Renewable energy integration | Reduced carbon footprint |

| Circular design principles | Enhanced product recyclability |

| Modular product design | Extended product lifespan |

Selecting the Right EMS Provider

The choice of an EMS provider can significantly impact product quality, market timing, and business success. The ideal partner combines comprehensive manufacturing capabilities with personalized service, effectively balancing scale with flexibility to meet specific client requirements.

Evaluating Experience and Expertise

- Industry-specific experience and regulatory compliance knowledge

- Portfolio of completed projects in relevant product categories

- Technical expertise across multiple disciplines

- Robust knowledge management systems

- Continuous training programs

- Specialized manufacturing process capabilities

- Quality assurance protocols

Assessing Technology and Innovation

Technological capability serves as a vital differentiator among EMS providers, directly influencing manufacturing quality, efficiency, and future-readiness. When evaluating potential partners, focus on their equipment portfolio, technology investment patterns, and innovation roadmap.

- Advanced production equipment implementation

- Automated quality control systems

- Sophisticated inventory management platforms

- AI-powered defect detection capabilities

- Advanced robotics integration

- Digital twin simulation technologies

During facility tours, examine the age and capabilities of their equipment, particularly for specialized processes essential to your product manufacturing. The most valuable partners demonstrate clear strategies for adapting to industry shifts and proactively suggest technological improvements to enhance both cost efficiency and quality. This forward-thinking approach ensures sustained support as products evolve and market demands change.

Importance of Communication and Collaboration

| Communication Element | Expected Features |

|---|---|

| Communication Infrastructure | Designated points of contact, regular updates, clear escalation pathways |

| Response Protocol | Quick response times, clear information delivery, direct issue resolution |

| Partnership Approach | Team integration, expertise sharing, optimization focus |

| Project Management | Detailed attention from inception to delivery, timeline adherence |

Superior EMS providers demonstrate genuine interest in understanding your business objectives and production needs, viewing success through the lens of client satisfaction rather than merely completing manufacturing tasks. Their collaborative approach should be evident through previous client partnerships and successful management of challenging projects, ensuring comprehensive support throughout the manufacturing journey.