Brick Manufacturing Machine: The Key to Efficient Construction

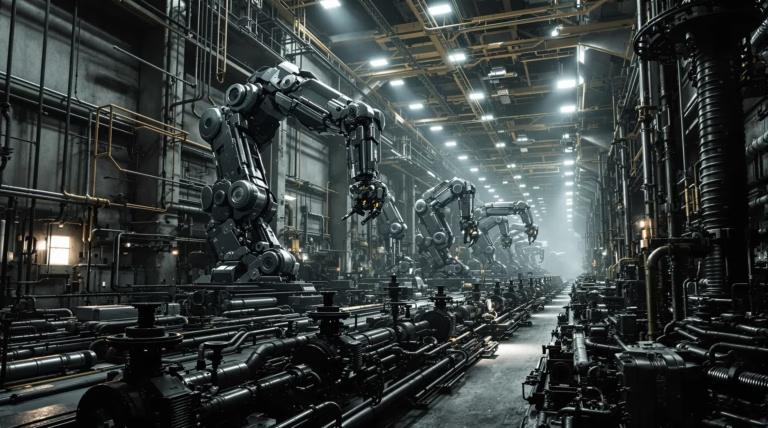

In today’s rapidly evolving construction industry, brick manufacturing machines stand as essential tools for builders and contractors seeking to optimize their operations. Whether you’re planning to start a construction business or upgrade your existing facility, understanding these machines can significantly impact your project’s success. Let’s explore the comprehensive world of brick manufacturing technology and its transformative impact on modern construction.

Understanding Brick Manufacturing Machines

Brick manufacturing machines have revolutionized the construction industry by enhancing production efficiency and ensuring consistent brick quality. These specialized machines automate the traditionally labor-intensive process of brick-making, enabling higher production capacity and standardized output. Modern brick machines feature various automation levels and specialized capabilities designed to meet specific construction requirements.

The evolution of brick manufacturing technology has dramatically reduced construction timelines and costs. Contemporary machines can produce thousands of bricks daily with minimal human intervention, making them invaluable assets for construction companies aiming to optimize their operations.

Types of Brick Manufacturing Machines

- Manual Brick Machines – entry-level options ideal for small businesses and startups, requiring human operation but offering advantages over traditional methods

- Semi-automatic Machines – balanced solutions featuring motorized mixing and compression components while requiring some manual intervention

- Fully Automatic Machines – advanced systems with integrated material feeding, mixing, molding, curing, and stacking capabilities, suitable for large-scale operations

Materials Used in Brick Production

| Material Type | Characteristics | Applications |

|---|---|---|

| Clay | Traditional material, excellent durability, aesthetic appeal | Residential construction, heritage buildings |

| Cement-based | Adjustable strength, weather resistant | Commercial construction, pavements |

| Specialized Mixtures | Enhanced properties with additives like fly ash or slag | Custom construction projects, specific environmental conditions |

Benefits of Using Brick Manufacturing Machines

Modern brick machines, such as the QT5-15 Paver Brick Machine, offer comprehensive automation and versatility in production. These systems can produce various products including hollow blocks, solid blocks, concrete bricks, and interlocking pavers, providing flexibility for different project requirements.

Cost Efficiency and Savings

- Significant reduction in labor costs through automation

- Precise material dosing systems minimizing waste

- Elimination of transportation costs through on-site production

- Return on investment typically achieved within 12-18 months

- Increased production volume with minimal supervision

Energy Efficiency in Brick Machines

Energy efficiency stands as a critical advantage of modern brick manufacturing machines, directly impacting operational costs and environmental footprint. Advanced hydraulic systems optimize power consumption by distributing energy precisely where needed during the production cycle, contrasting sharply with traditional methods that often waste significant power through inefficient processes.

- Variable frequency drives adjust motor speeds based on production requirements

- Improved insulation systems minimize energy loss

- Heat recovery systems in curing chambers reduce power consumption

- Targeted energy distribution eliminates wasteful idle running

- Optimized hydraulic systems ensure precise power allocation

These energy-efficient technologies not only lower electricity bills but also contribute to sustainability goals by reducing carbon emissions. For construction companies seeking both economic and environmental benefits, energy-efficient brick manufacturing machines represent an intelligent investment that aligns with modern building industry standards while delivering ongoing operational savings.

Choosing the Right Brick Manufacturing Machine

Investing in the appropriate brick manufacturing machine can significantly impact your construction business’s productivity and profitability. The market offers various models with different production capacities, automation levels, and price points. Premium machines like the QT4-15 Automatic Block Construction Manufacturing Brick Making Machine ($7,900-$9,900) typically deliver superior durability, better production consistency, and enhanced operational efficiency.

Factors to Consider When Selecting a Machine

| Factor | Considerations |

|---|---|

| Budget Planning | Initial costs, financing options, ROI timeframes, service life projection |

| Production Capacity | Daily/monthly brick requirements, growth potential, peak production periods |

| Brick Types | Solid blocks, hollow blocks, interlocking pavers, specialty designs |

| Manufacturer Reputation | Component quality, training support, after-sales service reliability |

Importance of Customer Feedback

Customer feedback provides invaluable insights that technical specifications alone cannot convey. Before finalizing your purchase, investigate customer reviews and ratings across multiple platforms to identify patterns regarding reliability, actual production capacity, and support quality.

- Direct feedback from current users about day-to-day operations

- Real-world performance assessments under various conditions

- Quality of pre-sale consultation and product information

- Responsiveness of post-purchase support

- Manufacturer’s commitment to quality control and inspection

Training and Maintenance for Brick Machines

Effective training and proper maintenance are critical components for maximizing the lifespan and efficiency of brick manufacturing machines. A well-maintained brick machine operates more efficiently and produces higher-quality products with fewer defects, ultimately protecting your investment and ensuring consistent production quality.

Training Programs for Machine Operators

- Fundamental operation principles and startup procedures

- Troubleshooting techniques and safety protocols

- Early detection of potential issues

- Hands-on training sessions with theoretical instruction

- Ongoing refresher courses for evolving technology

- Specialized training for different skill levels

Well-trained operators contribute significantly to overall productivity by recognizing erratic machine behavior and preventing defective product production. This proactive approach enables timely maintenance interventions and ensures optimal machine performance throughout its operational life.

Maintenance Tips for Longevity

Regular maintenance is the foundation of brick machine longevity and consistent performance. A structured daily inspection routine enables operators to monitor critical components effectively. This proactive approach focuses on essential system checks and preventive measures.

- Daily inspection of hydraulic systems and fluid levels

- Verification of electrical connections and wiring integrity

- Assessment of mechanical parts for wear patterns

- Thorough cleaning to prevent material buildup

- Implementation of manufacturer-recommended lubrication schedules

- Monitoring of molds and compression systems

| Maintenance Component | Key Activities |

|---|---|

| Preventative Schedule | Based on operating hours rather than calendar dates |

| Component Management | Proactive replacement of worn parts, pressure calibration |

| System Monitoring | Belt tension adjustment, electrical system verification |

| Documentation | Detailed maintenance logs, issue tracking, failure prediction |

For organizations lacking internal technical expertise, establishing a maintenance contract with the manufacturer or authorized service provider ensures professional care. This approach often reduces overall maintenance costs through early problem detection and expert intervention, ultimately extending the machine’s operational life while maintaining optimal performance standards.