Electronics Manufacturing: Key Insights and Processes Explained

Step into the fascinating world of electronics manufacturing, where innovation meets precision to create the devices that power our daily lives. From smartphones to medical equipment, this industry shapes the future of technology while driving global economic growth.

Understanding Electronics Manufacturing: Definition and Importance

Electronics manufacturing encompasses the comprehensive process of designing, assembling, and producing electronic components and devices. This industry serves as the foundation for numerous sectors, including:

- Consumer electronics and telecommunications

- Medical equipment and devices

- Automotive systems and controls

- Industrial automation equipment

- Aerospace and defense technology

The process involves multiple critical stages, from electronic design to final packaging, ensuring products meet rigorous quality standards. As technology evolves rapidly, manufacturers continuously adapt to new materials, processes, and methodologies, revolutionizing how we live, work, and communicate.

What is Electronics Manufacturing?

Electronics manufacturing transforms raw materials and components into functional electronic products through specialized processes. This discipline operates at the intersection of electrical engineering, materials science, and manufacturing technology, distinguished by its:

- Precision requirements at micrometer levels

- Stringent cleanliness standards

- Advanced automated processes

- Comprehensive testing procedures

- Sophisticated quality control measures

The Role of Electronics Manufacturing in the Global Economy

The industry generates trillions in annual revenue and employs millions worldwide, creating extensive supply chains across continents. Its impact extends through:

| Sector | Impact |

|---|---|

| Healthcare | Advanced medical devices and diagnostic equipment |

| Transportation | Revolutionary automotive electronics systems |

| Communication | Mobile technology and digital infrastructure |

| Business | Digital transformation and automation solutions |

Key Processes in Electronics Manufacturing

Modern electronics manufacturing combines advanced technologies with precision equipment to create increasingly complex devices. This structured approach ensures consistent quality while maintaining efficiency and scalability across production volumes.

Design and Prototyping

The manufacturing journey begins with comprehensive design and prototyping phases, utilizing:

- Computer-Aided Design (CAD) software for detailed schematics

- Multiple prototype iterations for testing and validation

- 3D printing for rapid prototyping

- Small-batch PCB fabrication for concept verification

- Rigorous testing protocols for performance optimization

Assembly Techniques: SMT and THT

Electronics manufacturing relies on two fundamental assembly methods: Surface Mount Technology (SMT) and Through-Hole Technology (THT). SMT represents the more sophisticated approach, where components mount directly onto the PCB surface, enabling:

- Higher component density placement

- Reduced form factor designs

- Enhanced high-frequency performance

- Faster automated assembly

- Lower production costs at scale

The SMT process involves precise solder paste application through stencils, automated component placement, and controlled reflow soldering. Through-Hole Technology, while traditional, remains vital for specific applications. THT components insert through pre-drilled board holes, providing superior mechanical strength for high-stress or high-power components.

Testing and Quality Control

A comprehensive testing and quality control framework ensures product reliability through multiple verification stages:

| Testing Phase | Purpose |

|---|---|

| In-circuit Testing (ICT) | Verifies individual component functionality and placement |

| Functional Testing | Evaluates performance under various operating conditions |

| Environmental Testing | Assesses durability under temperature, humidity, and vibration stress |

| Automated Optical Inspection | Detects visual defects and misalignments |

| X-ray Inspection | Examines hidden solder connections beneath components |

Types of Electronics Manufacturing: Contract vs. In-house

The electronics industry operates through two primary production models: contract manufacturing and in-house production. Each approach offers distinct advantages and operational implications, influencing factors such as capital expenditure, operational costs, quality control, and time-to-market efficiency.

Advantages and Disadvantages of Contract Manufacturing

Contract manufacturing presents several strategic benefits:

- Reduced capital investment requirements

- Access to advanced production capabilities

- Flexible production scaling

- Lower operational overhead

- Rapid market entry potential

However, significant challenges exist, including quality control complexities, intellectual property protection concerns, and potential communication barriers. Companies must carefully evaluate these tradeoffs against their specific business requirements and long-term strategic objectives.

In-house Production: Pros and Cons

In-house electronics manufacturing delivers exceptional control over production processes and quality standards. This direct oversight enables swift quality control implementation, immediate issue resolution, and streamlined design-to-production transitions. Companies benefit from enhanced intellectual property protection by keeping proprietary designs and technologies within their facilities. The approach also accelerates innovation through close collaboration between engineering and manufacturing teams.

- Direct process control and quality oversight

- Rapid implementation of manufacturing changes

- Enhanced intellectual property protection

- Seamless engineering-manufacturing collaboration

- Faster design iterations and improvements

| Challenge | Impact |

|---|---|

| Initial Investment | High costs for facilities, equipment, and personnel |

| Fixed Overhead | Ongoing maintenance regardless of production volume |

| Expertise Requirements | Need for specialized manufacturing and compliance knowledge |

| Scale Economics | Potentially higher per-unit costs compared to contract manufacturing |

Materials and Technologies in Electronics Manufacturing

Modern electronics manufacturing leverages an extensive range of specialized materials and cutting-edge technologies. The industry’s evolution has been driven by continuous innovations in materials science, enabling the creation of increasingly complex and miniaturized devices. Advanced materials, including flexible electronics, nanomaterials, and specialized polymers, have revolutionized manufacturing capabilities and product performance.

Printed Circuit Boards and Their Role

Printed Circuit Boards (PCBs) form the foundation of electronic devices, providing both mechanical support and electrical connectivity. These sophisticated platforms feature copper pathways and traces etched onto non-conductive substrates, enabling complex electronic circuits to function through structured signal routing between components.

The PCB manufacturing process encompasses multiple critical stages, from initial design to final assembly. Engineers develop detailed schematics and translate them into physical layouts using Gerber files. Assembly utilizes either Surface Mount Technology (SMT) for direct component mounting or Through-Hole Technology (THT) for components requiring additional mechanical strength. Modern devices often incorporate multilayer PCBs, enabling complex circuitry in compact spaces.

Semiconductors and Components

Semiconductors represent the cornerstone of modern electronics, enabling precise control of electrical current flow through materials like silicon, gallium arsenide, and germanium. The semiconductor industry operates through a sophisticated ecosystem of equipment manufacturers, design firms, and fabrication facilities.

- Advanced wafer fabrication processes

- Precision photolithography techniques

- Specialized etching and doping procedures

- Continuous evolution following Moore’s Law

- Integration of flexible electronics and nanomaterials

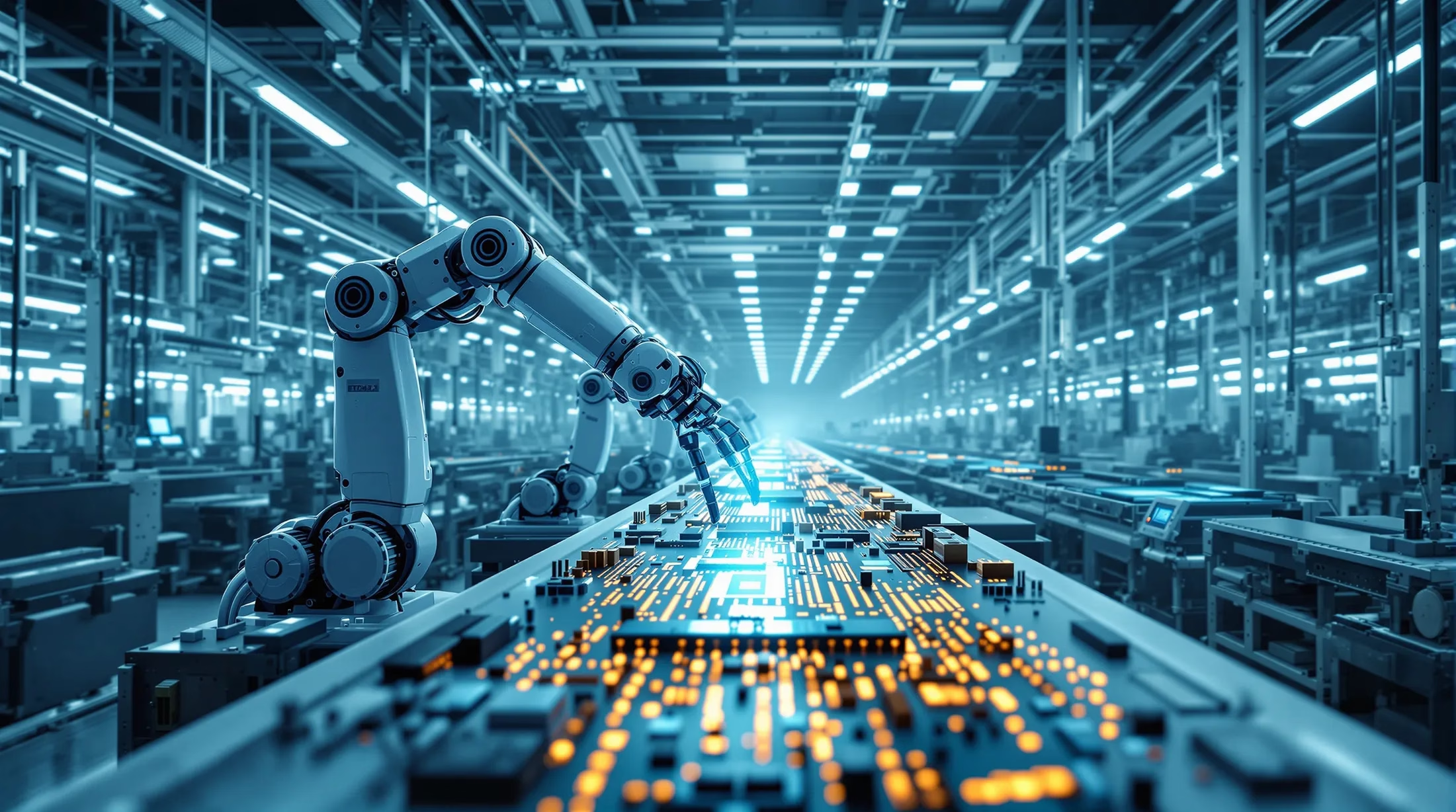

The Impact of Automation and Robotics

Automation and robotics have revolutionized electronics manufacturing, delivering unprecedented precision, efficiency, and scalability. Smart manufacturing technologies, powered by artificial intelligence and machine learning, coordinate sophisticated production lines through interconnected networks of sensors, automated guided vehicles, and robotic arms. These advancements have proven essential in high-volume consumer electronics production, where scale and efficiency determine market competitiveness.

How Automation Enhances Efficiency

Automation delivers remarkable efficiency gains in electronics manufacturing through multiple mechanisms. Advanced pick-and-place machines position thousands of components per hour with microscopic precision, while automated optical inspection systems detect defects invisible to the human eye. These capabilities accelerate production and minimize rework by catching issues early in the process.

- Dramatically reduced cycle times for repetitive tasks

- Enhanced precision in component placement

- Automated defect detection and inspection

- Consistent parameter maintenance for critical processes

- Higher first-pass yields and reduced defect rates

- Real-time process data collection and analysis

The Role of Robotics in Modern Manufacturing

Industrial robots have become indispensable in modern electronics manufacturing, excelling at tasks requiring precision, strength, and repetition. Six-axis robotic arms handle delicate components with submillimeter accuracy, while collaborative robots (cobots) work alongside human operators, performing heavy lifting and repetitive tasks.

| Robotics Feature | Manufacturing Benefit |

|---|---|

| Advanced Vision Systems | Component identification and manipulation regardless of orientation |

| Improved End Effectors | Dexterous handling of fragile electronic parts |

| Automated Hazardous Processes | Enhanced workplace safety and reduced exposure to harmful substances |

| Integration Rate | 73% of manufacturers utilize robotics in production lines |

Sustainability and Environmental Compliance

The electronics manufacturing industry is experiencing a significant transformation toward sustainability, driven by consumer demands, stricter regulations, and corporate responsibility initiatives. Companies are implementing comprehensive measures addressing the entire product lifecycle, from energy consumption reduction to waste minimization and recyclable material incorporation.

Sustainable Practices in Electronics Manufacturing

- Ethical sourcing of rare earth metals and materials

- Implementation of energy-efficient production techniques

- Transition to renewable energy sources (40% carbon emission reduction)

- Closed-loop manufacturing systems for material recapture

- Biodegradable packaging alternatives

- Water conservation with 80% reuse capability

Regulatory Standards and Compliance

The industry operates within a complex regulatory framework designed to minimize environmental impact. Key regulations include the Restriction of Hazardous Substances (RoHS) directive and the Waste Electrical and Electronic Equipment (WEEE) directive, establishing strict standards for material usage and recycling targets.

| Compliance Element | Implementation Strategy |

|---|---|

| Material Tracking | ERP systems with specialized compliance modules |

| Documentation | Automated regulatory reporting and record-keeping |

| Voluntary Certifications | EPEAT and Energy Star programs |

| Future Preparedness | Adoption of standards exceeding current requirements |

Future Trends in Electronics Manufacturing

The electronics manufacturing industry is undergoing a transformative evolution driven by technological innovation, shifting consumer demands, and sustainability imperatives. Market projections indicate substantial growth, with the industry expected to reach $643.37 billion by 2029, growing at a 5.0% compound annual rate. This expansion is powered by revolutionary production methodologies that enhance efficiency, flexibility, and customization capabilities.

Manufacturing facilities are evolving into intelligent ecosystems, where automation and robotics lead the transformation. Smart factories leverage interconnected systems for unprecedented production optimization through real-time monitoring and adaptive workflows. Sustainability has become a core business strategy, with manufacturers integrating circular economy principles into product design, focusing on repairability, recyclability, and environmental impact reduction.

The Rise of AI and IoT

- Real-time workflow optimization through AI algorithms

- Predictive maintenance capabilities

- Automated production parameter adjustment

- Comprehensive digital monitoring systems

- 67% productivity improvement post-IoT implementation

- Autonomous equipment communication

- Real-time inventory management

- Predictive quality control systems

Predictions for the Next Decade

| Innovation Area | Expected Impact |

|---|---|

| Digital Twin Technology | Virtual simulation and optimization of production environments |

| Advanced Materials | Enhanced durability and environmental sustainability of components |

| Manufacturing Localization | Regional production hubs closer to end markets |

| Mass Customization | Efficient small-batch production without cost penalties |

| Sustainability Integration | Enhanced environmental performance and resource efficiency |