Heavy Fabrication Services: Expert Solutions for Your Projects

Looking to understand the complexities of heavy fabrication services? Whether you’re involved in aerospace, construction, or industrial manufacturing, these specialized metal fabrication processes play a crucial role in creating large-scale structures and components. Let’s explore the essential aspects of heavy fabrication and how it’s revolutionizing modern manufacturing.

Understanding Heavy Fabrication Services

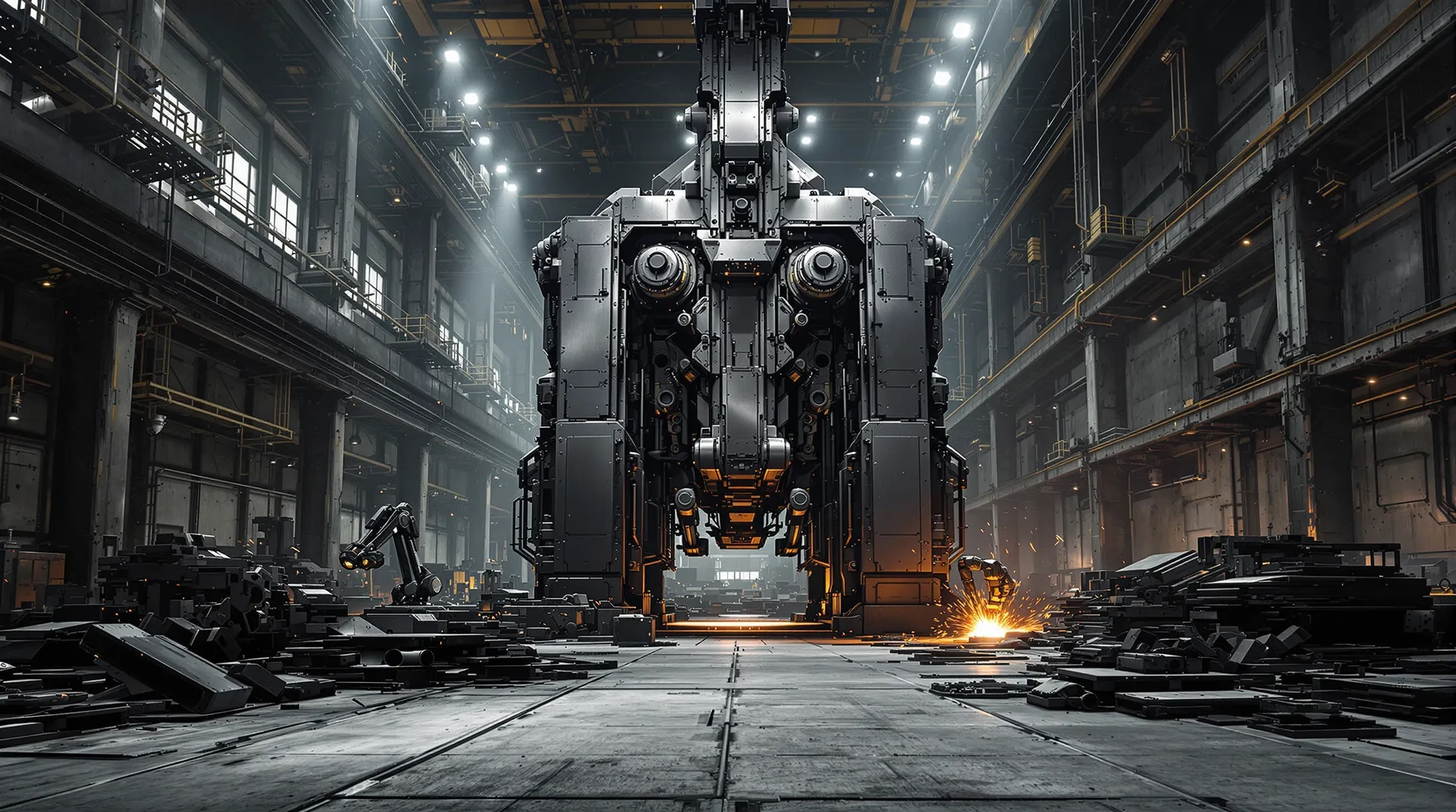

Heavy fabrication services encompass specialized manufacturing processes designed for creating large-scale metal structures and components. These services involve the manipulation, cutting, forming, and joining of substantial metal pieces to produce industrial-grade products that meet precise specifications. By combining advanced technology with skilled craftsmanship, heavy fabrication facilities deliver custom metal fabrication solutions that satisfy the demanding requirements of complex projects.

The comprehensive nature of heavy fabrication extends beyond basic manufacturing to include:

- Design consultation and planning

- Material selection and sourcing

- Advanced fabrication processes

- Rigorous quality control measures

- Post-production services and support

What is Heavy Fabrication?

Heavy fabrication refers to metalworking processes focused on producing large, complex metal structures and components that typically weigh tons rather than pounds. Unlike light fabrication, which deals with smaller products like furniture or hand tools, heavy fabrication operations often take place in expansive facilities equipped with specialized machinery capable of handling substantial materials.

| Component Examples | Required Equipment |

|---|---|

| Ship hulls, Airframes, Industrial boilers | Plate roll machines, Heavy-duty presses |

| Storage tanks, Structural frameworks | Industrial-scale cutting systems, Welding equipment |

Key Industries Served by Heavy Fabrication

The aerospace industry relies heavily on fabrication services for producing critical components like airframes, landing gear structures, and engine mounts. These parts require exceptional precision, adherence to strict safety standards, and the ability to withstand extreme conditions.

- Aerospace – Critical components with strict safety standards

- Construction – Structural beams, trusses, and architectural elements

- Industrial machinery – Pressure vessels and conveyor systems

- Energy sector – Power generation equipment and infrastructure

- Defense industry – Military vehicles and naval vessels

- Mining operations – Excavation and processing equipment

- Transportation – Railway components and shipping terminals

Advanced Techniques in Heavy Fabrication

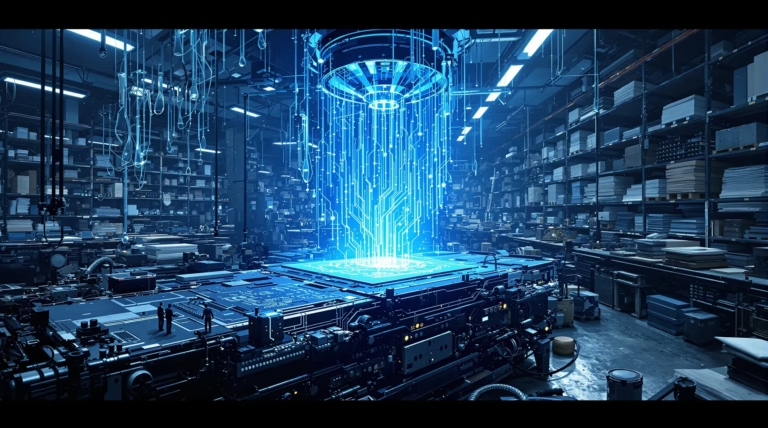

The landscape of heavy fabrication has been revolutionized by technological advancements that enhance precision, efficiency, and productivity. Modern fabrication facilities now integrate sophisticated technologies that transform the manufacturing process from design to completion.

The Role of CNC Machining in Fabrication

Computer Numerical Control (CNC) machining stands at the forefront of precision engineering in heavy fabrication, enabling manufacturers to execute complex operations with remarkable accuracy. CNC systems transform digital designs into precise commands that control fabrication equipment, eliminating human error and ensuring consistent results across production runs.

- Precision milling and drilling operations

- Automated turning and routing capabilities

- Multi-material processing flexibility

- Consistent quality across large workpieces

- Reduced production time through automation

Laser Cutting for Precision and Efficiency

Laser cutting technology has revolutionized metal fabrication by delivering unmatched precision in material processing. This advanced technique employs focused light beams to cut through metal with exceptional accuracy, producing clean edges and minimal heat-affected zones. The precision engineering enables fabricators to create intricate patterns and complex geometries that would be impossible with traditional methods, maintaining tolerances within fractions of a millimeter.

- High-speed operation while maintaining accuracy

- Rapid switching between cutting patterns without tooling changes

- Minimal material waste through efficient part nesting

- Reduced kerf width for optimal material utilization

- Consistent results for demanding specifications

Robotic Welding: Enhancing Quality and Speed

Robotic welding systems have transformed heavy fabrication through unparalleled consistency and precision. These automated systems execute complex welding sequences with perfect repeatability, ensuring uniform weld quality across entire production runs. Advanced sensors and sophisticated programming maintain optimal parameters throughout the process, including:

- Precise travel speed control

- Consistent arc length maintenance

- Optimal heat input regulation

- Complex geometry navigation

- Adaptive joint configuration handling

The implementation of robotic welding delivers significant productivity gains, performing in hours what would take human welders days to complete. These systems excel particularly in industries with stringent quality requirements like aerospace, defense, and infrastructure, providing both the precision and documentation necessary for rigorous certification standards while maintaining competitive production rates.

Materials and Techniques in Heavy Fabrication

Heavy fabrication projects require materials that offer exceptional strength, durability, and resistance to harsh conditions. Modern facilities utilize diverse metals and alloys, each selected for specific applications and environmental demands. The evolution of fabrication techniques combines traditional craftsmanship with cutting-edge technology, employing specialized equipment capable of handling substantial loads and applying controlled force to shape thick metal components.

Common Materials Used in Heavy Fabrication

| Material Type | Key Applications | Properties |

|---|---|---|

| Carbon Steel | General structural components | Variable strength, good workability |

| Stainless Steel | Corrosive environments | Excellent durability, corrosion resistance |

| Aluminum Alloys | Aerospace, marine applications | High strength-to-weight ratio, corrosion resistant |

| Specialized Alloys | Extreme conditions | Custom properties for specific requirements |

Metal Forming and Rolling Techniques

Metal forming processes transform flat sheets into three-dimensional shapes through controlled force application. Advanced equipment includes press brakes capable of hundreds of tons of pressure and sophisticated hydraulic presses for complex component formation. The rolling process employs massive plate roll machines with multiple rollers to create precise curved sections and cylindrical forms, essential for:

- Storage tank fabrication

- Wind tower section production

- Pressure vessel end formation

- Variable radius bending operations

- Thick material handling with pyramid-style machines

Choosing the Right Heavy Fabrication Partner

Selecting the ideal heavy fabrication partner represents a critical decision that directly influences project outcomes, timelines, and success rates. The best fabricators deliver more than manufacturing capabilities – they bring comprehensive expertise, innovative approaches, and collaborative solutions aligned with specific project needs.

- Technical capabilities and equipment sophistication

- Industry-specific experience and expertise

- Quality control processes and standards

- Schedule adherence and budget management

- Problem-solving capabilities and innovation

- Resource availability and scalability

Evaluating Fabrication Capabilities and Certifications

When assessing potential fabrication partners, focus on their technical infrastructure and facility specifications. Essential evaluation criteria include equipment portfolio, manufacturing space, and material handling capabilities.

| Certification | Significance | Industry Application |

|---|---|---|

| AISC | Structural steel fabrication quality | Construction, Infrastructure |

| ASME | Pressure vessels and boilers compliance | Energy, Industrial Processing |

| AWS | Welding expertise verification | Multiple Industries |

| ORI | Mission-critical operations excellence | Defense, Aerospace |

Custom Solutions for Diverse Client Needs

Leading fabricators excel in developing tailored solutions through collaborative consultation and comprehensive understanding of project requirements. Their client-centric approach optimizes material usage, production efficiency, and performance characteristics while meeting specific project parameters.

- Design optimization services for improved manufacturability

- Material selection expertise and consultation

- Comprehensive project management solutions

- Quality assurance protocols and documentation

- Specialized surface treatment options

- Integrated subassembly services

- Advanced logistics coordination