Industrial Manufacturing Company: Leading Innovations and Solutions

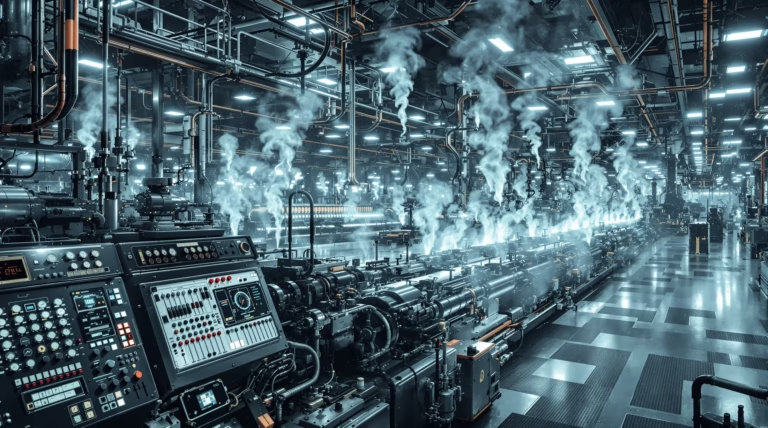

Discover how industrial manufacturing companies are revolutionizing the global economy through innovation, sustainability, and technological advancement. From pioneering automation solutions to creating millions of high-value jobs, these organizations are shaping our future in remarkable ways.

The Role of Industrial Manufacturing Companies in the Global Economy

Industrial manufacturing companies form the backbone of the global economy, serving as crucial engines of growth, innovation, and employment. These organizations transform raw materials into finished products that power virtually every sector—from automotive and aerospace to consumer goods and healthcare. With a global market value exceeding $15 trillion, the manufacturing sector contributes approximately 16% to the world’s GDP, making it one of the most influential economic drivers worldwide.

- Creates 2.5 additional jobs in related sectors for each manufacturing position

- Accounts for 70% of private-sector R&D investment

- Drives technological advancement across industries

- Establishes international trade networks connecting global economies

- Stimulates innovation through extensive supply chains

Significance of Industrial Manufacturing

Industrial manufacturing serves as the foundation of modern economic systems by converting raw materials into finished products at scale. This transformation process represents a sophisticated ecosystem that generates tremendous economic value. Manufacturing creates high-quality employment opportunities, with over 12 million direct manufacturing jobs in the United States alone and hundreds of millions worldwide.

| Economic Impact Factor | Value |

|---|---|

| Wage Premium vs. Service Sector | 12-25% higher |

| Export Contribution | 67% in developed economies |

| Economic Multiplier Effect | $1.81 per dollar invested |

Key Players in the Industrial Manufacturing Sector

The industrial manufacturing landscape features diverse players ranging from century-old conglomerates to agile, specialized firms. Companies like Siemens, with over 300,000 employees across 190 countries, exemplify the scale of major manufacturing entities. Meanwhile, firms such as ABB, Honeywell, and Emerson Electric have established themselves as market leaders by consistently delivering innovative industrial solutions while adapting to changing technological paradigms.

Innovations Driving the Industrial Manufacturing Industry

The industrial manufacturing sector is experiencing an unprecedented technological revolution, with innovations reshaping production processes across the globe. This transformation is fundamentally altering how products are designed, fabricated, and distributed, creating competitive advantages for forward-thinking companies.

- Productivity increases of 15-30% in the first year of implementation

- Cost reductions of 10-20% through technological adoption

- 50% reduction in equipment downtime through AI-powered maintenance

- 35% decrease in quality issues with IoT-connected factory floors

- Significant improvements in real-time production monitoring

Automation and Robotics in Manufacturing

Automation and robotics have revolutionized manufacturing operations, delivering unprecedented levels of precision, consistency, and operational efficiency. Modern industrial robots can perform complex tasks with sub-millimeter accuracy at speeds several times faster than human workers, working continuously without fatigue or variation.

| Robotics Impact | Performance Metric |

|---|---|

| Error Rate Reduction | Up to 90% |

| Cobot Cost Savings | 75% vs. traditional robots |

| Productivity Increase | 20% average |

| Material Handling Cost Reduction | Up to 40% |

The Impact of AI and IoT Technologies

Artificial intelligence and Internet of Things technologies are fundamentally transforming manufacturing by creating smart, interconnected production environments. These advanced systems analyze massive datasets from production lines, delivering unprecedented optimization capabilities. Early-adopting facilities have achieved remarkable results:

- Energy consumption reduction of up to 20%

- Material waste reduction of 25%

- 32% faster time-to-market for new products

- 12% increase in customer satisfaction scores

- 400% reduction in data processing latency through edge computing

IoT connectivity serves as the nervous system of modern manufacturing, with advanced facilities generating up to 1TB of production data daily. This constant stream of information enables real-time decision-making and powers digital twins – virtual replicas of physical production systems that enable risk-free simulation and optimization.

Sustainable Practices in Industrial Manufacturing

Sustainable manufacturing represents a paradigm shift in industrial production, focusing on environmental stewardship while maximizing economic returns. This comprehensive approach delivers measurable benefits:

| Benefit Category | Impact |

|---|---|

| Operational Costs | 12% reduction |

| Brand Reputation | 15% improvement |

| Resource Costs | 34% lower |

| Productivity | 16% higher |

Importance of Sustainability in Manufacturing

Manufacturing operations significantly impact global environmental metrics, accounting for 22% of greenhouse gas emissions and 54% of world energy resources. Companies implementing comprehensive sustainability programs achieve substantial improvements:

- 40% reduction in waste generation

- 30% decrease in energy consumption

- 25% reduction in water usage

- 27% higher employee satisfaction

- 31% lower turnover rates

Case Studies of Sustainable Manufacturing Companies

Siemens exemplifies excellence in sustainable manufacturing through its comprehensive program, achieving a 54% reduction in carbon emissions while increasing production output by 23%. Their Amberg Electronics Plant demonstrates exceptional results:

- 75% lower energy consumption compared to standard facilities

- Annual savings exceeding €11 million

- Integration of smart grid technology

- Implementation of AI-optimized production processes

- Renewable energy system utilization

Interface, a global flooring manufacturer, showcases similar success through its Mission Zero initiative, achieving 88% reduction in water usage, 96% decrease in greenhouse gas emissions, and zero waste to landfill across all facilities. Their material reclamation programs divert 15 million pounds of carpet from landfills annually, generating documented savings of $450 million over 20 years.

Challenges and Solutions in Industrial Manufacturing

Modern manufacturers face significant operational challenges that impact efficiency and profitability. Unplanned downtime affects 82% of facilities, with costs reaching $260,000 per hour in lost production. Forward-thinking companies are implementing comprehensive solutions that deliver measurable improvements:

- 40% reduction in downtime through predictive maintenance

- 35% improvement in quality consistency

- Enhanced worker safety through automated monitoring

- Streamlined production processes

- Improved market competitiveness

Overcoming Supply Chain Challenges

Today’s manufacturing supply chains face unprecedented complexity due to globalization, dynamic market conditions, and frequent disruptions. The COVID-19 pandemic exposed critical vulnerabilities, with industrial product companies struggling to meet customer demands. These challenges have prompted manufacturers to shift from efficiency-focused strategies toward building resilient supply networks.

- Supplier diversification reducing disruption impacts by up to 60%

- AI-powered forecasting tools improving demand prediction accuracy by 85%

- Collaborative transportation systems enhancing delivery reliability by 30%

- Real-time supply chain visibility enabling proactive disruption management

- Enhanced supplier partnerships strengthening operational continuity

Addressing Workforce Training Needs

The manufacturing sector faces a critical workforce challenge as skilled workers approach retirement age, while attracting younger talent proves increasingly difficult. This demographic shift is complicated by new generations’ digital expectations and the growing complexity of manufacturing processes.

| Training Innovation | Impact |

|---|---|

| Virtual Reality Training | 40% faster skill acquisition, 75% better retention |

| Enhanced Workplace Conditions | 35% improved recruitment, 28% higher retention |

| Technical School Partnerships | Sustainable talent pipeline development |

The Future of Industrial Manufacturing

The manufacturing sector stands at the threshold of transformation, driven by digital technologies, advanced materials, and innovative production methods. Industry forecasts indicate that companies investing in future-focused technologies can achieve 30-50% productivity gains within the next decade, while significantly reducing operational costs.

The evolution features increasing system interconnectivity, autonomous production processes, and unprecedented customization capabilities. 3D printing technology, growing at 23.5% CAGR through 2028, is revolutionizing both prototyping and small-batch production, enabling previously impossible geometric complexities.

Emerging Technologies and Their Impact

- Additive manufacturing reducing assembly requirements by 30%

- Material waste reduction of 40% compared to traditional methods

- AR systems decreasing assembly errors by 32%

- 25% faster task completion with AR-assisted operations

- Quantum computing enabling advanced material development

The convergence of these technologies creates multiplicative effects, exponentially increasing manufacturing capabilities while reducing development cycles from years to weeks in certain sectors. The additive manufacturing market alone is projected to reach $55.8 billion by 2027, highlighting the significant economic impact of these technological advances.

The Role of Customer-Centric Approaches

A profound shift toward customer-centricity is redefining success parameters in industrial manufacturing. Companies implementing comprehensive customer experience strategies demonstrate remarkable advantages:

- 25% higher customer satisfaction scores

- 18% faster growth rates

- 42% better customer retention

- Enhanced product lifecycle support

- Improved initial engagement metrics

Digital transformation serves as the cornerstone of this customer-centric revolution. Leading manufacturers leverage data analytics to identify unmet needs and preference patterns, creating products that precisely address market requirements. Digital platforms provide unprecedented order visibility, from design customization through production tracking and delivery scheduling. Forward-thinking manufacturers are extending this approach through product-as-a-service models, enabling predictive maintenance and continuous performance optimization.

Collaboration and Partnerships in Manufacturing

Strategic partnerships have emerged as critical drivers of innovation and competitive advantage in today’s complex manufacturing landscape. Companies fostering collaborative relationships demonstrate significant improvements:

| Performance Metric | Improvement |

|---|---|

| Innovation Rates | 37% higher |

| Time-to-Market | 29% faster |

| Development Costs | 23% reduction |

| Resource Utilization | 42% improvement |

Building Strategic Partnerships

Manufacturing partnerships represent carefully cultivated relationships delivering mutual value through complementary capabilities. Companies engaged in strategic partnerships report:

- 45% greater access to innovation resources

- 31% improved ability to meet specialized market demands

- 3.4x greater value from partnerships with cultural commitment

- Enhanced knowledge sharing capabilities

- Streamlined intellectual property management

Case Studies of Successful Collaborations

Boeing’s 787 Dreamliner program exemplifies large-scale manufacturing collaboration, achieving remarkable results through its global partner network:

- $4 billion reduction in development costs

- 2-year decrease in time-to-market

- Unprecedented fuel efficiency achievements

- Enhanced passenger comfort through specialized expertise

- Improved subsystem integration

Smaller manufacturers demonstrate equally impressive results. Prototek’s cross-departmental collaboration system reduced response times to quality feedback by 68% and decreased production errors by 43%. Chemours’ strategic partnership with a logistics provider yielded a 35% reduction in inventory costs and 28% improvement in on-time delivery performance.