Injection Molding Manufacturer: Your Guide to Quality Production

Looking to transform your manufacturing process with precision and efficiency? Injection molding manufacturing offers a cutting-edge solution for businesses seeking high-quality, consistent production at scale. Let’s explore how this versatile manufacturing method can revolutionize your production capabilities.

Understanding Injection Molding Manufacturing

Injection molding manufacturing represents one of the most precise and efficient production methods in modern industry. This process involves injecting molten material—typically plastic—into custom-designed mold cavities, where it cools and solidifies into the desired shape. The process’s versatility and efficiency have established it as a cornerstone of production across numerous industries worldwide.

When collaborating with an injection molding manufacturer, companies gain access to specialized equipment and expertise that enables mass production of complex parts with exceptional consistency. Custom plastic injection molding services deliver tailored solutions for specific product requirements, optimizing both design and material selection.

What is Injection Molding?

Injection molding follows a systematic cycle that ensures precise and repeatable results. Here’s how the process works:

- Plastic pellets are heated to their melting point

- Molten material is forcefully injected into the closed mold under high pressure

- Material cools and solidifies within the mold cavity

- Mold opens to eject the finished component

- The cycle repeats for continuous production

The Role of an Injection Molding Manufacturer

An injection molding manufacturer provides comprehensive services throughout the production lifecycle, including:

- Technical expertise and advanced equipment operation

- Design optimization for improved moldability

- Material selection guidance

- Production parameter optimization

- Quality control and testing procedures

Key Features of a Quality Injection Molding Manufacturer

Leading injection molding manufacturers distinguish themselves through a combination of technical excellence, robust infrastructure, and rigorous quality controls. ISO 9001:2015 certification serves as a baseline requirement, demonstrating commitment to internationally recognized quality management standards.

Certification and Standards

| Certification Type | Application |

|---|---|

| ISO 9001:2015 | Quality management systems and operations |

| FDA Registration | Medical device components |

| ITAR Compliance | Defense-related parts |

| Automotive Certifications | Vehicle components |

In-House Tooling and Design Capabilities

Premium manufacturers offer integrated tooling departments that provide:

- Rapid prototyping and mold modification capabilities

- Design for manufacturability (DFM) analysis

- Material flow optimization

- Gate placement and wall thickness considerations

- Draft angle optimization

- Cycle time reduction strategies

Innovative Services Offered by Injection Molding Manufacturers

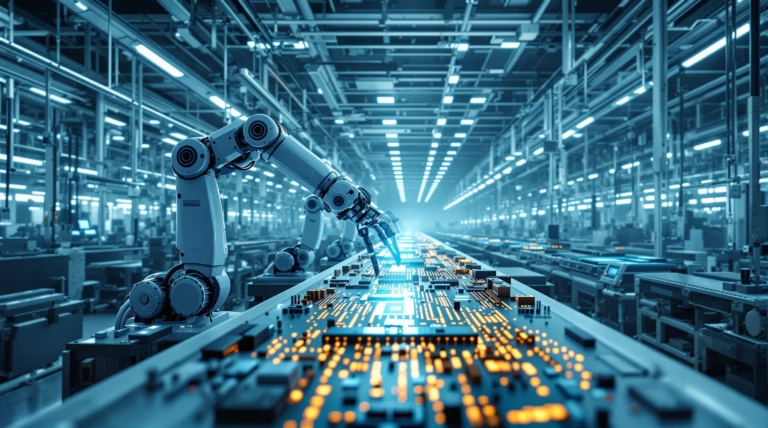

Today’s leading injection molding manufacturers distinguish themselves through comprehensive service offerings that extend beyond basic production. These companies deliver end-to-end solutions spanning the entire product lifecycle, integrating advanced technologies with customer-focused approaches to create exceptional value across industries.

- Complete end-to-end services under one roof

- Real-time production monitoring systems

- Advanced inventory management solutions

- Integrated design and engineering support

- Streamlined communication channels

- Supply chain visibility tools

Prototyping and Product Development

Modern injection molding manufacturers leverage sophisticated rapid prototyping technologies to transform concepts into functional models efficiently. These prototypes enable thorough design validation and functionality testing before investing in production tooling.

- 3D printed concept models

- Machined functional prototypes

- Low-volume injection molded samples

- Comprehensive engineering support

- Design optimization for manufacturability

- Material selection consultation

Advanced Tracking and Quality Assurance

| Quality Control Element | Benefits |

|---|---|

| RFID Tracking Technology | Real-time monitoring, inventory management, regulatory compliance |

| Automated Vision Systems | Dimensional accuracy verification, visual inspection |

| Coordinate Measuring Machines | Precise component measurement, quality verification |

| Customized Quality Reporting | Detailed metrics, statistical process control data |

Applications of Injection Molding in Various Industries

Injection molding serves as a fundamental manufacturing process across multiple sectors, delivering precision, scalability, and cost-efficiency. This versatile technology enables the production of complex components ranging from automotive parts to medical devices, meeting stringent quality and regulatory requirements.

Electronics and Consumer Goods

- Smartphone cases and laptop housings

- Circuit board enclosures with EMI shielding

- Connectors and internal components

- Household appliances and kitchenware

- Toys and recreational products

- In-mold decorated consumer items

Modern injection molding techniques facilitate advanced features like multi-material overmolding and specialized surface finishes, eliminating secondary processing while maintaining competitive pricing and consistent quality. These capabilities enable manufacturers to create market-ready products that combine functionality with aesthetic appeal.

Medical and Healthcare Devices

The medical and healthcare industries depend on injection molding for producing critical components that meet stringent safety and performance standards. These specialized manufacturers create essential items using medical-grade plastics like polycarbonate, PEEK, and silicones, ensuring products that maintain stability through sterilization processes while delivering precise tolerances.

- Surgical instruments and tools

- Diagnostic equipment components

- Drug delivery systems

- Implantable medical devices

- Microfluidic diagnostic cartridges

- Custom prosthetics components

Sustainability in Injection Molding Manufacturing

Leading injection molding manufacturers are embracing eco-friendly practices throughout their production processes, responding to environmental concerns and regulatory requirements. This sustainability focus delivers multiple benefits through reduced operational costs, enhanced brand reputation, and alignment with environmentally conscious consumer preferences.

| Sustainable Practice | Implementation |

|---|---|

| Energy Management | Energy-efficient machinery, closed-loop cooling systems, optimized production schedules |

| Resource Conservation | Renewable energy adoption, comprehensive recycling programs |

| Process Optimization | Carbon footprint reduction, waste minimization strategies |

Using Sustainable Materials

- Bioplastics from renewable resources

- Recycled polymers for various applications

- Biodegradable compound options

- Gas-assisted injection molding techniques

- Microcellular foaming processes

- Co-injection molding with recycled cores

Reducing Environmental Impact

Modern injection molding facilities implement comprehensive environmental strategies utilizing real-time monitoring systems to track resource consumption and optimize operations. These manufacturers provide detailed environmental impact assessments, measuring carbon footprint, water usage, and waste generation metrics.

- Closed-loop production systems

- Near-zero waste initiatives

- Strategic recycling partnerships

- Precision tooling optimization

- Process control improvements

- Resource consumption monitoring