Manufacturing Career Cluster: Explore Pathways and Opportunities

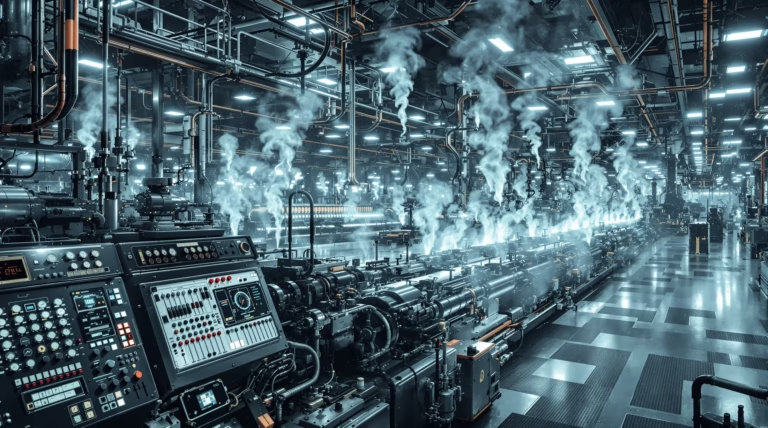

Looking to build a rewarding career in manufacturing? The Manufacturing Career Cluster offers diverse pathways and opportunities for those interested in transforming raw materials into finished products. Discover how this dynamic field combines technical expertise with innovation to shape the future of industry.

Understanding the Manufacturing Career Cluster

The Manufacturing Career Cluster represents one of 16 designated pathways in career and technical education (CTE). This comprehensive framework prepares individuals for careers in planning, designing, managing, and maintaining manufacturing systems. Through practical skill development and specialized knowledge, students learn to navigate modern manufacturing environments effectively.

What is the Manufacturing Career Cluster?

This specialized educational pathway focuses on careers involving hands-on work with materials and equipment. Students develop expertise in:

- Production processes and quality control

- Safety protocols and regulations

- Technological applications in manufacturing

- Product design and development

- Material handling and processing

Importance of Manufacturing in the Economy

Manufacturing serves as a cornerstone of economic strength, driving innovation and productivity across nations. Here are the key economic impacts:

- Contributes approximately 11% to U.S. GDP

- Supports over 12 million direct jobs nationwide

- Creates a multiplier effect – each manufacturing job supports 2.5 additional jobs

- Offers 13% higher wages compared to other industries

- Ensures national security through domestic production capabilities

Exploring Manufacturing Pathways

The Manufacturing Career Cluster encompasses six distinct pathways, each offering unique opportunities for professional growth. These structured routes enable individuals to develop specialized skills while working with various materials and technologies.

Production Pathway

| Key Roles | Required Skills | Education Level |

|---|---|---|

| Design Engineer | Technical expertise, materials science knowledge | Bachelor’s degree |

| Manufacturing Technician | Process control, equipment operation | Technical certification |

| Production Manager | Leadership, operations management | Bachelor’s degree |

Maintenance, Installation, and Repair Pathway

This pathway focuses on maintaining peak equipment efficiency and minimizing production downtime. Professionals in this field require:

- Strong troubleshooting abilities

- Technical knowledge of mechanical and electrical systems

- Specialized equipment training

- Post-secondary technical education or apprenticeship experience

- Continuous learning to keep pace with technological advances

Quality Assurance Pathway

The Quality Assurance Pathway centers on maintaining product excellence through rigorous testing and monitoring. Professionals in this field ensure manufactured items consistently meet performance, reliability, and safety standards.

- Quality Control Technicians – perform regular product inspections and testing

- Calibration Technicians – maintain measurement accuracy of testing equipment

- Quality Engineers – develop and implement quality management systems

- Lab Technicians – conduct detailed product analysis and testing

- SPC Coordinators – monitor statistical process control data

| Essential Skills | Educational Requirements |

|---|---|

| Meticulous attention to detail | Technical certifications |

| Strong analytical capabilities | Engineering degrees |

| Knowledge of quality standards | Statistical analysis training |

Logistics and Inventory Control Pathway

The Logistics and Inventory Control Pathway optimizes material flow throughout manufacturing operations. This critical function ensures efficient movement, storage, and tracking of resources from raw materials to finished products.

- Logistical Engineers – design and optimize supply chain systems

- Traffic Managers – coordinate transportation and delivery schedules

- Dispatchers – manage real-time material movement

- Material Handlers – operate material handling equipment

- Shipping/Receiving Clerks – process incoming and outgoing materials

Opportunities and Roles in Manufacturing

Modern manufacturing offers diverse career paths that combine traditional skills with advanced technology. The sector provides stable employment with competitive compensation, typically exceeding similar industries. Professionals can specialize in production planning, quality control, maintenance, automation, or research and development, contributing to both organizational success and economic growth.

Key Roles in Manufacturing

Today’s manufacturing environment encompasses specialized positions that support the entire production process. CNC programmers create precise machine instructions, while industrial engineers optimize workflows and reduce waste. Production supervisors lead teams and ensure safe, efficient operations, working alongside quality control specialists who maintain product standards.

Emerging Roles with Advanced Technologies

- Robotics Technicians – program and maintain automated systems

- Additive Manufacturing Specialists – operate and optimize 3D printing processes

- IoT Systems Integrators – connect and monitor smart factory equipment

- Manufacturing Data Analysts – transform production data into actionable insights

- Augmented Reality Specialists – develop AR interfaces for production processes

- Advanced Materials Engineers – implement new manufacturing materials

Education and Training for Manufacturing Careers

The Manufacturing Career Cluster provides comprehensive educational frameworks for transforming raw materials into finished products. This specialized path combines technical knowledge, practical skills, and hands-on experience beyond traditional academic programs. As manufacturing technologies advance, targeted educational programs have become increasingly vital for industry success.

- High school technical programs

- Associate degrees in manufacturing

- Bachelor’s programs in engineering

- Specialized industry certifications

- Industry partnership training

Importance of Technical Education

Technical education serves as the foundation of manufacturing workforce development, delivering specialized knowledge that directly translates to workplace success. The curriculum focuses on essential competencies including blueprint reading, CNC programming, material science, quality control procedures, and equipment operation.

| Industry Challenges | Technical Education Solutions |

|---|---|

| Aging workforce | New skilled graduates |

| Skills gaps | Current, relevant training |

| Technology advancement | Industry-recognized credentials |

Apprenticeships and On-the-Job Training

Manufacturing apprenticeships combine structured learning with paid work experience under expert mentorship. These 1-4 year programs enable mastery of complex skills while earning wages and avoiding educational debt.

- Mechatronics specialization

- Tool and die making

- Industrial maintenance

- Advanced manufacturing technology

- Equipment operation

- Process-specific training

Future Trends in the Manufacturing Career Cluster

Industry 4.0 represents a convergence of digital technology, data analytics, and traditional manufacturing processes. This transformation creates unprecedented opportunities while reshaping required professional skill sets. Smart factories are becoming standard, bringing increased efficiency and market responsiveness.

Impact of Automation and AI

- Robotics systems for repetitive tasks

- AI-powered predictive maintenance

- Machine learning for production optimization

- Automated quality control processes

- Data-driven decision making

These technological advances create new roles such as robotics specialists, manufacturing data analysts, and AI implementation technicians. For professionals willing to upskill, these changes offer pathways to higher-paying positions where human expertise remains essential in an increasingly automated environment.

Sustainability and Environmental Assurance

Sustainability has evolved from a peripheral concern to a central focus in modern manufacturing operations. Companies are reimagining production processes to minimize environmental impact through reduced energy consumption, decreased waste generation, and lower carbon emissions. This shift is driven by a combination of regulatory requirements, consumer demands, and recognition of long-term business benefits.

- Reduced resource consumption

- Lower waste management expenses

- Enhanced regulatory compliance

- Improved environmental performance

- Strengthened brand reputation

The Health, Safety, and Environmental Assurance pathway within the Manufacturing Career Cluster has gained new prominence as sustainability becomes essential to manufacturing operations. This evolution has created several emerging career opportunities:

| Role | Primary Responsibilities |

|---|---|

| Sustainability Manager | Oversee company-wide green initiatives and environmental programs |

| Environmental Compliance Specialist | Navigate complex regulations and ensure regulatory adherence |

| Circular Economy Engineer | Design products and processes for waste minimization through reuse and recycling |

These positions represent growing opportunities for professionals who combine technical manufacturing knowledge with expertise in environmental systems and sustainable practices. The integration of sustainability into manufacturing operations continues to create new roles that bridge production efficiency with environmental responsibility.