Manufacturing Facilities Near Me: Find the Best Options in Your Area

Looking to optimize your production capabilities or explore local industrial opportunities? Discovering the right manufacturing facilities in your vicinity can significantly impact your business success and operational efficiency. Let’s explore how to find and leverage local manufacturing resources effectively.

Understanding Manufacturing Facilities Near Me

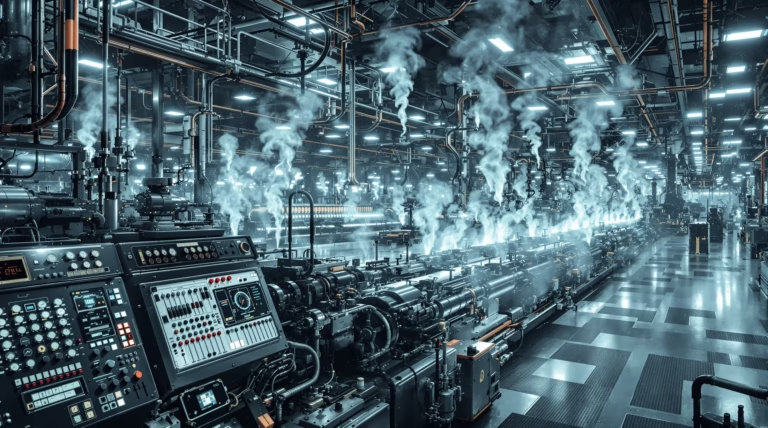

Manufacturing facilities serve as crucial industrial production centers across the nation. These specialized premises combine equipment, skilled personnel, and infrastructure to transform raw materials into finished products. Whether you’re seeking production services, employment opportunities, or potential business partnerships, understanding local manufacturing operations is essential for making informed decisions.

What Are Manufacturing Facilities?

Manufacturing facilities are industrial sites engineered for the production of goods through various transformation processes. These operations typically include:

- Production floors with specialized equipment

- Assembly lines for systematic production

- Quality control stations

- Warehousing areas for materials and finished goods

- Administrative offices

- Energy efficiency systems

Modern facilities range from compact specialized workshops to extensive industrial complexes, with an increasing focus on sustainable practices and energy-efficient operations to enhance competitiveness and reduce costs.

Importance of Local Manufacturing Facilities

Local manufacturing facilities offer distinct advantages that directly impact business success:

- Reduced shipping times and transportation costs

- Just-in-time delivery capabilities

- Enhanced market responsiveness

- Lower inventory requirements

- Improved cash flow management

- Stronger local economic development

- Direct access for facility visits and quality control

How to Find the Best Manufacturing Facilities Near Me

Finding suitable manufacturing facilities requires a strategic approach combining digital resources, traditional research methods, and professional networks. The goal is to identify facilities that align with your specific production needs while offering optimal efficiency and value.

Using Online Tools and Resources

| Resource Type | Examples | Benefits |

|---|---|---|

| Industry Directories | Thomasnet, MFG.com, IndustryNet | Detailed filtering, capability information, certification details |

| Geographic Tools | Google Maps, GIS applications | Visual location mapping, industrial zone identification |

| Government Resources | State economic databases | Official listings, local manufacturer information |

Consulting Local Business Directories

Traditional business directories remain valuable resources for identifying manufacturing facilities. Key sources include:

- Chamber of Commerce listings

- Regional business journals

- Manufacturing magazines

- Municipal industrial development agencies

- Local government industrial databases

These resources often reveal established manufacturers with proven track records who may not have significant online visibility but offer exceptional production capabilities and expertise.

Networking with Industry Professionals

Professional connections provide invaluable manufacturing facility recommendations through direct industry experience. Trade shows and manufacturing expos serve as centralized hubs where you can evaluate multiple facilities and meet their representatives face-to-face. These events enable efficient comparison of options while gathering detailed information about capabilities, availability, and specializations that may not be evident through online research.

- Industry association networking events for local manufacturing connections

- Supply chain professional consultations for hidden facility recommendations

- Trade show interactions for direct facility evaluations

- Industry consultant insights into specialized capabilities

- Professional relationship building for preferential partnerships

Evaluating Manufacturing Facilities in Your Area

Finding the optimal manufacturing facilities requires systematic evaluation across multiple dimensions beyond location and pricing. A comprehensive assessment helps identify facilities that combine the right capabilities, technologies, and operational efficiency to meet your production requirements.

Consider both immediate production needs and future scalability potential. Manufacturing facilities vary significantly in their specializations, equipment capabilities, and production capacity. Developing a structured assessment framework enables objective comparison of local options, ensuring selection of partners capable of delivering consistent quality while adapting to evolving production demands.

Key Factors to Consider

- Space utilization and layout efficiency

- Equipment capabilities and technological advancement

- Material handling and workflow optimization

- Loading dock accessibility and configuration

- Facility flexibility for future growth

- Worker safety and ergonomic considerations

- Training programs and quality outcomes

Comparing Facility Capabilities and Services

| Evaluation Category | Key Elements to Assess |

|---|---|

| Core Manufacturing Capabilities | Machinery specifications, production capacity, specialized processes |

| Value-Added Services | Design assistance, prototyping, quality testing, packaging, inventory management |

| Quality Management | ISO certifications, consistency records, sample products |

| Operational Factors | Communication processes, project management, response times |

Benefits of Choosing Local Manufacturing Facilities

Local manufacturing partnerships offer strategic advantages through reduced transportation costs and enhanced operational agility. This proximity enables efficient inventory management, improved cash flow, and greater flexibility in responding to market demands. Direct facility access allows for immediate quality control through personal inspections and face-to-face collaboration, while faster turnaround times help capitalize on time-sensitive opportunities.

Economic Impact on the Community

- Creation of diverse employment opportunities

- Stable income generation for local residents

- Enhanced local business spending

- Strengthened regional supply chains

- Economic diversification through specialized expertise

- Increased community resilience to market fluctuations

Environmental Considerations

The environmental benefits of choosing local manufacturing facilities extend far beyond basic operational advantages. By significantly reducing shipping distances, these facilities minimize carbon emissions associated with both raw material transport and finished product delivery.

- Reduced transportation carbon footprint through shorter delivery routes

- Implementation of energy-efficient equipment and processes

- Advanced waste reduction and recycling programs

- Water conservation initiatives and sustainable resource management

- Integration of renewable energy solutions

- Development of closed-loop material systems

- Enhanced recycling partnerships between local businesses

| Sustainable Practice | Environmental Impact |

|---|---|

| Local Sourcing | Reduced transportation emissions, smaller carbon footprint |

| Energy Management | Lower power consumption, decreased greenhouse gas emissions |

| Waste Programs | Minimized landfill impact, increased material recovery |

| Water Conservation | Reduced water usage, improved resource efficiency |

As environmental regulations become more stringent and consumer preferences shift toward sustainable products, these eco-friendly manufacturing practices transform from ethical initiatives into essential competitive advantages. The proximity of local facilities enables more effective implementation of sustainability programs, creating measurable environmental benefits while meeting market demands for responsible production practices.