Manufacturing Machines: Top 10 Essential Equipment for Your Business

In today’s rapidly evolving industrial landscape, manufacturing machines serve as the cornerstone of production efficiency and innovation. Whether you’re planning to upgrade your existing facility or establish a new manufacturing operation, understanding the right equipment can significantly impact your business success. Let’s explore the essential manufacturing machines that can revolutionize your production capabilities.

Understanding Manufacturing Machines

Manufacturing machines form the backbone of modern industrial production, transforming raw materials into finished products with precision and efficiency. These specialized pieces of equipment range from simple mechanical tools to complex automated systems that can perform multiple operations simultaneously.

- Enhanced precision and quality control

- Increased production rates

- Improved operational efficiency

- Reduced human error

- Greater competitive advantage

The Role of Manufacturing Machines in Industry

Manufacturing machines serve as the critical link between raw materials and finished goods, executing precise operations that would be impossible to achieve consistently by hand. In modern factories, these machines operate as part of integrated systems, each contributing to the overall production flow with specialized functions tailored to specific manufacturing needs.

| Industry Sector | Primary Applications |

|---|---|

| Automotive | Precision components, assembly lines |

| Aerospace | Complex parts manufacturing, testing |

| Consumer Goods | Mass production, packaging |

| Electronics | Circuit board assembly, testing |

Key Benefits of Using Manufacturing Machines

The implementation of manufacturing machines delivers substantial advantages for businesses optimizing their operations. Modern machinery can operate continuously with minimal downtime, significantly increasing production rates while maintaining consistent quality standards.

- Reduced labor requirements and associated costs

- Decreased material waste through precision operation

- Lower energy consumption with efficient models

- Enhanced quality control capabilities

- Improved scalability and market adaptability

Top 10 Essential Manufacturing Machines for Your Business

Selecting the right manufacturing equipment is crucial for businesses looking to establish or upgrade their production capabilities. The proper machinery determines the quality, scale, and diversity of products you can offer, directly impacting your ability to meet customer demands and maintain profitability.

CNC Machines: Precision and Efficiency

Computer Numerical Control (CNC) machines represent the pinnacle of precision manufacturing, allowing businesses to produce complex components with exceptional accuracy. These automated cutting machines follow programmed instructions to remove material from workpieces, creating intricate parts with tolerances as tight as 0.001 inches.

Injection Moulding Machines: Mass Production Solutions

Injection moulding machines enable businesses to produce identical parts in massive quantities with remarkable efficiency. These powerful systems force molten material into custom-designed molds under high pressure, creating precisely formed components in seconds, with cycle times ranging from 15 to 120 seconds per part.

Laser Cutters: Precision Cutting Technology

Laser cutting technology has revolutionized manufacturing by providing unprecedented precision and versatility in material processing. These machines harness concentrated light energy to cut, engrave, or mark materials with exceptional accuracy—often achieving tolerances within 0.1mm.

- Non-contact cutting eliminates tool wear issues

- Ensures consistent quality across production runs

- Reduces maintenance costs significantly

- Processes diverse materials including metals, plastics, wood, textiles, and composites

- Creates complex geometries impossible with conventional tools

The digital workflow of laser cutting streamlines production processes and enables rapid design iterations. This technology offers significant advantages in terms of setup time, material utilization, and production flexibility, allowing manufacturers to respond quickly to changing customer requirements while maintaining high-quality standards.

3D Printers: Prototyping and Low-Volume Manufacturing

3D printing technology has transformed product development by dramatically reducing prototyping time and costs. These additive manufacturing systems build objects layer by layer directly from digital designs, enabling concept materialization within hours instead of weeks.

- Enables rapid testing of multiple design variations

- Reduces development risks and costs

- Supports various materials (plastics, resins, metals, ceramics)

- Excels in creating complex internal structures

- Ideal for customized products and consolidated assemblies

The technology has established itself in low-volume manufacturing scenarios, particularly in medical device manufacturing, aerospace, and custom consumer products. As print speeds increase and material options expand, 3D printing continues to bridge the gap between prototypes and mass production, offering new manufacturing possibilities with minimal upfront investment.

Packaging Machines: Ensuring Product Safety and Efficiency

Packaging machines automate crucial tasks including filling, sealing, wrapping, bagging, and labeling—operations that would be prohibitively labor-intensive if performed manually. In high-volume manufacturing environments, these systems can process thousands of units per hour while maintaining precise material usage and consistent quality.

| Feature | Benefit |

|---|---|

| Sterile environments | Ensures product safety and compliance |

| Tamper-evident seals | Protects brand reputation |

| Accurate dosing systems | Maintains product consistency |

| Flexible formatting | Adapts to market demands |

Industrial Mixers: Consistent Mixtures for Quality Production

Industrial mixers serve as critical equipment for achieving perfect material blending consistency. These machines come in various configurations, including ribbon blenders, paddle mixers, and high-shear mixers, each designed for specific mixing challenges across industries.

- Ensures thorough blending to exact specifications

- Offers precise control over speed, temperature, and duration

- Features automated feeding mechanisms

- Includes sampling ports for quality control

- Incorporates advanced cleaning systems

Modern industrial mixers support quality production at scale through sophisticated control systems that enable repeatable processes. Their versatility in handling diverse materials—from fine powders to viscous liquids—makes them essential tools across virtually all manufacturing segments.

Electric Generators: Power Continuity in Manufacturing

Electric generators provide manufacturing businesses with vital power continuity protection, safeguarding against costly production disruptions. These standby power systems automatically activate during utility failures, maintaining electricity supply to critical equipment and preventing material waste, production halts, and potential equipment damage.

- Protects continuous processes and temperature-sensitive operations

- Supports essential operations during extended outages

- Enables operational stability in regions with unreliable utilities

- Offers cost advantages during peak demand periods

- Features sophisticated monitoring and transfer systems

| Generator Consideration | Impact on Operations |

|---|---|

| Fuel Type Selection | Affects operational costs and reliability |

| Capacity Requirements | Determines production coverage during outages |

| Noise Limitations | Influences installation location and containment needs |

| Maintenance Schedule | Impacts long-term reliability and costs |

Compressors: High-Pressure Applications

Industrial compressors convert electrical energy into compressed air power, driving essential pneumatic equipment across manufacturing operations. These systems support diverse applications, from automotive assembly lines to plastic molding operations, establishing compressed air as the fourth utility after electricity, water, and natural gas.

- Powers assembly line tools and testing equipment

- Enables precise molding operations

- Features variable speed drives for energy optimization

- Provides specialized oil-free options for food production

- Delivers pressure ranges from 80 to 150 PSI

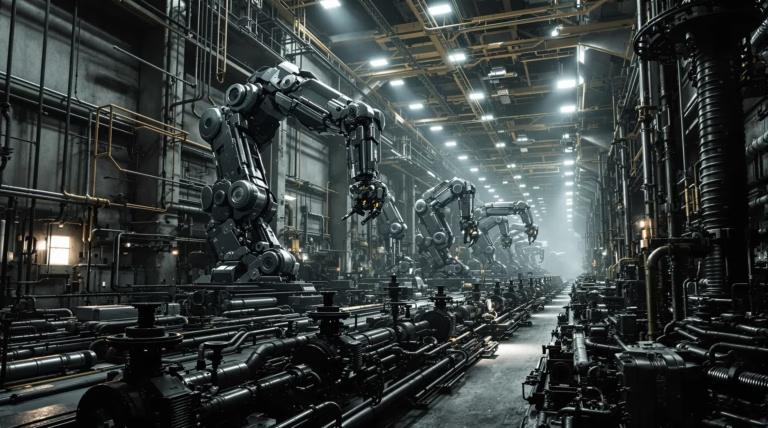

Robotics Integration: Enhancing Precision and Speed

Robotic systems revolutionize manufacturing through unmatched precision and speed capabilities. These automated solutions execute complex movements with sub-millimeter accuracy while maintaining consistent performance across extended production runs.

- Achieves precision levels eliminating secondary finishing

- Incorporates vision systems and advanced sensors

- Excels in repetitive tasks across all sectors

- Enhances worker safety and reduces labor costs

- Creates synchronized production environments

- Enables seamless machine-to-machine communication

Trends and Innovations in Manufacturing Machines

The manufacturing landscape continues to evolve through technological convergence, particularly with hybrid additive subtractive manufacturing (HASM) combining CNC precision with 3D printing capabilities. Industry 4.0 principles drive smart manufacturing integration, connecting physical production systems with digital networks. Artificial intelligence applications transform quality control, maintenance scheduling, and supply chain optimization, fundamentally changing how manufacturing businesses operate and compete in global markets.

Automation and Advanced Software in Manufacturing

Modern manufacturing automation extends far beyond basic robotic operations, incorporating sophisticated vision systems, advanced sensors, and machine learning algorithms. These intelligent systems enable real-time production adjustments by detecting subtle variations in materials and environmental conditions, optimizing parameters to maintain quality while reducing waste and energy usage. Digital twins – virtual replicas of physical equipment – enhance production capabilities by allowing manufacturers to simulate and refine processes before implementing physical changes.

- Real-time quality monitoring and adjustment capabilities

- Integrated vision systems for precise inspection

- Advanced sensing technology for environmental monitoring

- Machine learning algorithms for process optimization

- Digital twin simulation capabilities

- Automated parameter adjustment systems

Environmental Sustainability in Machine Design

Environmental considerations now form core design principles in manufacturing equipment development. Modern machinery incorporates energy-efficient components, regenerative systems that recover and reuse power, and intelligent management features that minimize consumption during idle periods. These innovations deliver both environmental benefits and significant cost savings through reduced utility expenses and extended equipment life.

| Sustainable Feature | Business Impact |

|---|---|

| Energy-efficient components | Lower operational costs |

| Regenerative systems | Reduced power consumption |

| Closed-loop water filtration | Decreased water usage |

| Precision manufacturing | Minimized material waste |

Conclusion: Choosing the Right Manufacturing Machines for Your Business

Selecting appropriate manufacturing equipment represents a pivotal decision that shapes productivity, operational efficiency, and product quality. The optimal alignment between machinery capabilities and production requirements can significantly enhance manufacturing performance and market competitiveness.

- Assess current production processes and bottlenecks

- Evaluate machine reliability and maintenance requirements

- Consider energy efficiency and system compatibility

- Balance initial investment against long-term benefits

- Factor in potential labor cost reductions

- Account for waste reduction capabilities

- Analyze product consistency improvements