Manufacturing Technician Job Description: Key Responsibilities and Skills

Looking to understand the vital role of a Manufacturing Technician in today’s industrial landscape? Discover the comprehensive responsibilities, work environment, and key functions that make this position essential for successful manufacturing operations.

Overview of the Manufacturing Technician Role

A manufacturing technician serves as a critical component in the production division of manufacturing companies. These skilled professionals ensure smooth and efficient production processes while operating, maintaining, and troubleshooting complex machinery across various industries.

While duties vary between companies and sectors, manufacturing technicians focus on:

- Maintaining quality standards

- Following safety protocols

- Optimizing production efficiency

- Managing equipment operation

- Performing preventive maintenance

What is a Manufacturing Technician?

A manufacturing technician is a skilled professional who bridges the gap between production operators and engineers. They possess specialized technical knowledge that enables them to set up, operate, monitor, and troubleshoot manufacturing equipment. These specialists typically report to production supervisors while collaborating with other technicians and production staff.

Unlike general production workers, technicians combine technical expertise with practical skills, understanding:

- Production workflows

- Equipment specifications

- Quality standards

- Problem-solving methodologies

- Specific machinery operations

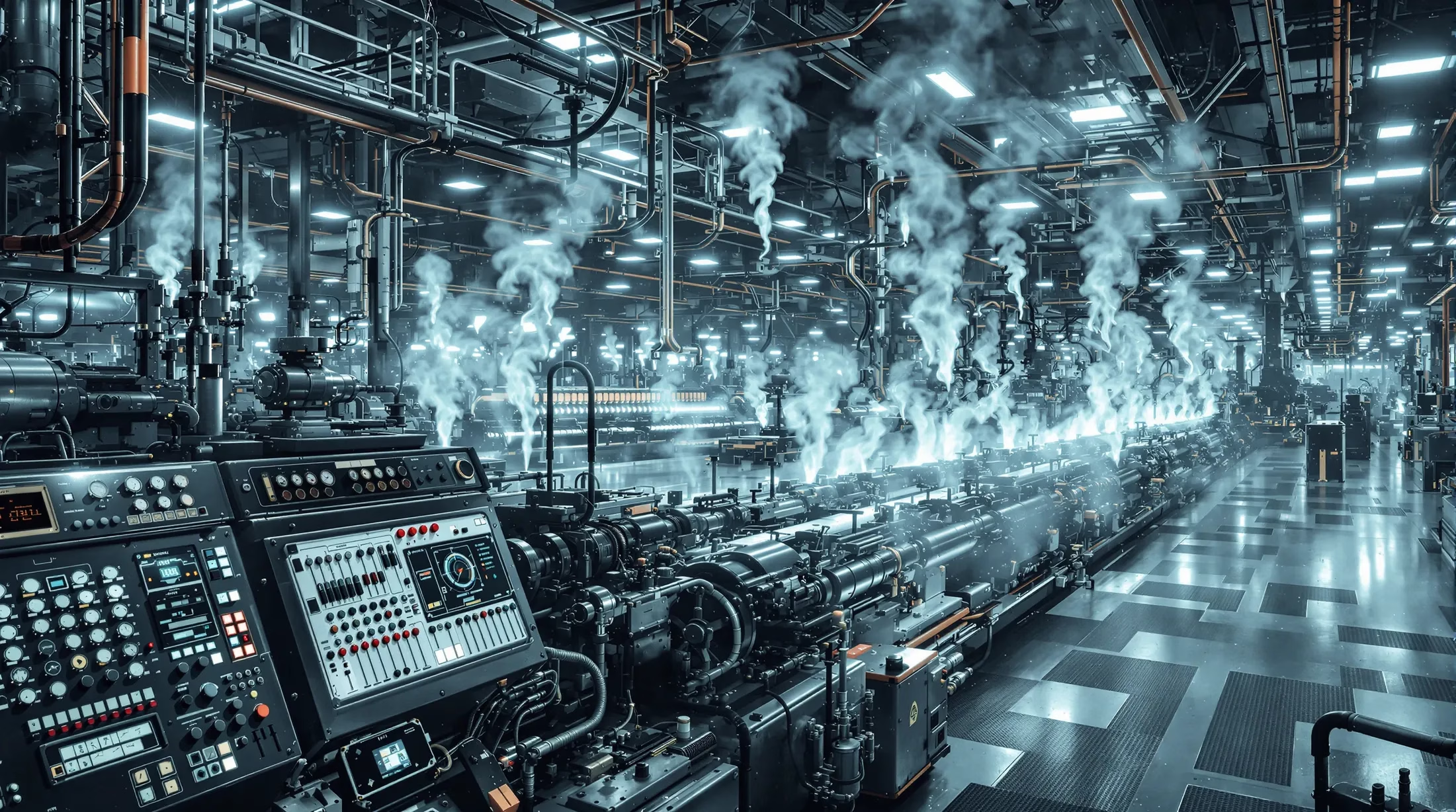

Work Environment and Conditions

Manufacturing technicians operate in diverse factory settings, from small production facilities to large industrial plants. Their work environment typically includes:

| Environmental Factors | Safety Requirements |

|---|---|

|

– Assembly lines – Specialized equipment areas – Testing stations – Climate-controlled spaces |

– Safety glasses – Hearing protection – Protective gloves – Steel-toed boots |

Key Responsibilities of a Manufacturing Technician

Manufacturing technicians function as operational cornerstones in production environments, managing diverse responsibilities that ensure efficient manufacturing processes and quality standards. They monitor production workflows, identify potential issues, and implement solutions before problems affect output.

Setting Up and Operating Production Lines

Initial responsibilities include configuring production lines according to specified requirements. This involves:

- Preparing and calibrating machinery

- Loading raw materials

- Verifying component functionality

- Interpreting technical specifications

- Monitoring automated systems

- Adjusting settings for optimal performance

Troubleshooting and Maintenance

Manufacturing technicians excel in diagnostic and maintenance tasks, including:

- Quick problem diagnosis and resolution

- Regular preventative maintenance execution

- Performance data analysis

- Equipment lifespan optimization

- System failure prevention

Conducting Quality Checks

Quality control represents a fundamental responsibility for manufacturing technicians who serve as the first line of defense against defective products. Throughout production runs, technicians perform systematic quality checks at predetermined intervals, inspecting products against established specifications and standards.

- Visual examination of product integrity

- Dimensional measurements verification

- Functional testing execution

- Specialized quality control instrument operation

- Performance characteristics validation

When defects or quality issues are identified, manufacturing technicians must determine whether to reject individual units or entire batches that fail to meet standards. They collaborate with quality assurance personnel to analyze defects, identify root causes, and implement corrective actions to prevent recurrence. Additionally, technicians often calibrate quality control equipment, maintain testing apparatus, and stay updated on industry standards and protocols.

Documentation and Reporting

Precise documentation forms an essential component of a manufacturing technician’s responsibilities. Technicians maintain detailed records across multiple areas:

- Production activities and metrics

- Equipment performance data

- Maintenance procedures

- Quality testing results

- Throughput rates and cycle times

- Defect percentages

- Equipment efficiency statistics

In regulated industries like pharmaceuticals or medical device manufacturing, documentation takes on additional importance, as technicians must maintain meticulous records that demonstrate adherence to strict regulatory requirements. These records support quality audits, provide traceability for compliance, and create historical performance data that informs process improvements and troubleshooting efforts.

Essential Skills for a Manufacturing Technician

Success as a manufacturing technician requires a comprehensive skill set that combines technical expertise with interpersonal capabilities. These professionals must blend hands-on mechanical knowledge with analytical thinking to navigate modern manufacturing environments effectively. The ideal candidate demonstrates proficiency across several core competency areas while maintaining the ability to adapt to changing priorities and contribute to continuous improvement initiatives.

Technical and Mechanical Aptitude

Strong technical and mechanical aptitude forms the cornerstone of a manufacturing technician’s skill set. Successful technicians must master:

- Blueprint and schematic interpretation

- Equipment manual comprehension

- Mechanical principles understanding

- Pneumatic and hydraulic systems operation

- Electrical circuit knowledge

- Automated controls management

- Computerized machinery operation

- PLC and MES system familiarity

Attention to Detail and Problem-Solving

Manufacturing technicians must possess exceptional attention to detail to ensure product quality and maintain production standards. This meticulousness enables them to:

- Spot subtle deviations in product specifications

- Identify minor equipment issues before major breakdowns

- Ensure precise adherence to production protocols

- Apply systematic diagnostic approaches

- Make data-driven decisions

- Implement effective solutions quickly

- Develop proactive maintenance strategies

Communication and Collaboration

Manufacturing technicians must excel in communication to effectively interact across departments. Their role requires clear articulation of technical issues to various stakeholders, from operators to management. Key communication responsibilities include:

- Explaining technical problems to non-technical staff

- Reporting production issues to supervisors

- Coordinating with maintenance teams

- Documenting procedures and quality deviations

- Managing maintenance logs with precision

- Facilitating shift handovers

The manufacturing environment demands strong teamwork abilities, as production floors operate as integrated systems. Technicians regularly collaborate with:

- Production operators

- Quality inspectors

- Engineers

- Maintenance personnel

- Cross-departmental teams

Time Management and Efficiency

In manufacturing environments, where production schedules directly impact profitability, effective time management is crucial. Successful technicians must:

- Prioritize tasks based on production impact

- Balance preventative maintenance with urgent repairs

- Coordinate quality inspections with production demands

- Manage unexpected troubleshooting efficiently

- Monitor production timeline impacts

- Develop standardized approaches for routine tasks

- Execute procedures consistently under pressure

Industries and Employment Opportunities

Manufacturing technicians enjoy diverse career opportunities across multiple industrial sectors. The field’s evolution with automation and digital technologies creates expanding roles for professionals who combine mechanical expertise with technological proficiency. Modern facilities seek technicians capable of managing both traditional systems and advanced digital platforms.

Industries Hiring Manufacturing Technicians

| Industry | Key Focus Areas |

|---|---|

| Automotive | Robotics, precision tooling, advanced materials |

| Electronics | Consumer electronics, control systems, semiconductors |

| Aerospace | Aircraft parts, propulsion systems, avionics |

| Medical Devices | Sterile manufacturing, precision components |

| Pharmaceuticals | Regulated production, quality control |

Job Growth and Specializations

Advanced manufacturing fields show particularly strong growth, especially in medical technology and pharmaceutical sectors. Career advancement opportunities include:

- CNC machine operation specialization

- Automation systems maintenance

- Clean room manufacturing expertise

- Quality control inspection

- Process improvement certification

- IoT systems management

- Predictive maintenance technology

- Leadership roles (team lead, shift supervisor)

Education and Training Requirements

Manufacturing technician positions require specific educational backgrounds and technical training to ensure competency in modern production environments. The sector has evolved to embrace both traditional educational pathways and alternative credentialing options, creating multiple entry points for aspiring technicians. With increasingly sophisticated manufacturing processes, employers prioritize formal education and technical certifications that demonstrate proficiency with modern production equipment and methodologies.

Minimum Educational Qualifications

Entry-level manufacturing technician positions typically require a high school diploma or GED equivalent as the baseline qualification. This ensures candidates possess fundamental skills in mathematics, science, and communication. Valuable high school coursework includes:

- Industrial arts

- Advanced mathematics

- Computer applications

- Basic electronics

- Technical sciences

Many employers now prefer candidates with additional technical education, particularly associate degrees in:

- Manufacturing technology

- Industrial maintenance

- Electronics engineering

- Mechanical technology

- Automation systems

Advanced Training and Certifications

Industry-recognized certifications validate specialized skills beyond basic educational requirements. Common certifications include:

- Certified Production Technician (CPT)

- Manufacturing Skill Standards Council (MSSC) certifications

- National Institute for Metalworking Skills (NIMS) credentials

- Automation technology certifications

- Robotics programming certificates

- PLC programming credentials

- Six Sigma methodologies

Salary, Benefits, and Physical Demands

Manufacturing technician compensation packages vary based on industry sector, location, experience level, and technical expertise. The field combines competitive salaries with comprehensive benefits, reflecting the increasing value of skilled technical labor in modern manufacturing.

Average Salary and Benefits

| Experience Level | Annual Salary Range |

|---|---|

| Entry-level | $30,000 – $35,000 |

| Median | $42,000 |

| Experienced/Specialized | $65,000+ |

Standard benefits packages include:

- Health insurance coverage

- Retirement plans

- Paid time off

- Shift differential pay

- Production-based bonuses

- Tuition reimbursement

- Technical certification sponsorship

- Career advancement opportunities

Physical Demands of the Job

Manufacturing technician positions require substantial physical capabilities to perform daily tasks effectively. The core physical requirements include:

- Strength to lift and handle components up to 50 pounds

- Manual dexterity for precise equipment adjustments

- Stamina for standing during 8-12 hour shifts

- Regular bending, stretching, and reaching movements

- Visual acuity for quality inspection and reading measurements

- Fine motor control for calibrating equipment

Technicians must perform these duties while wearing required personal protective equipment (PPE), including:

- Safety glasses

- Hearing protection

- Steel-toed boots

- Respirators (when required)

The work environment presents additional physical challenges through exposure to:

- Elevated temperatures

- Noise and vibration

- Temperature fluctuations

- Limited climate control

- Occasional hazardous materials

Specialized positions may require additional physical capabilities such as color vision discrimination, working in confined spaces, or performing tasks at heights. These physical demands are typically detailed in job descriptions to ensure candidates can safely execute essential job functions while maintaining workplace safety standards.