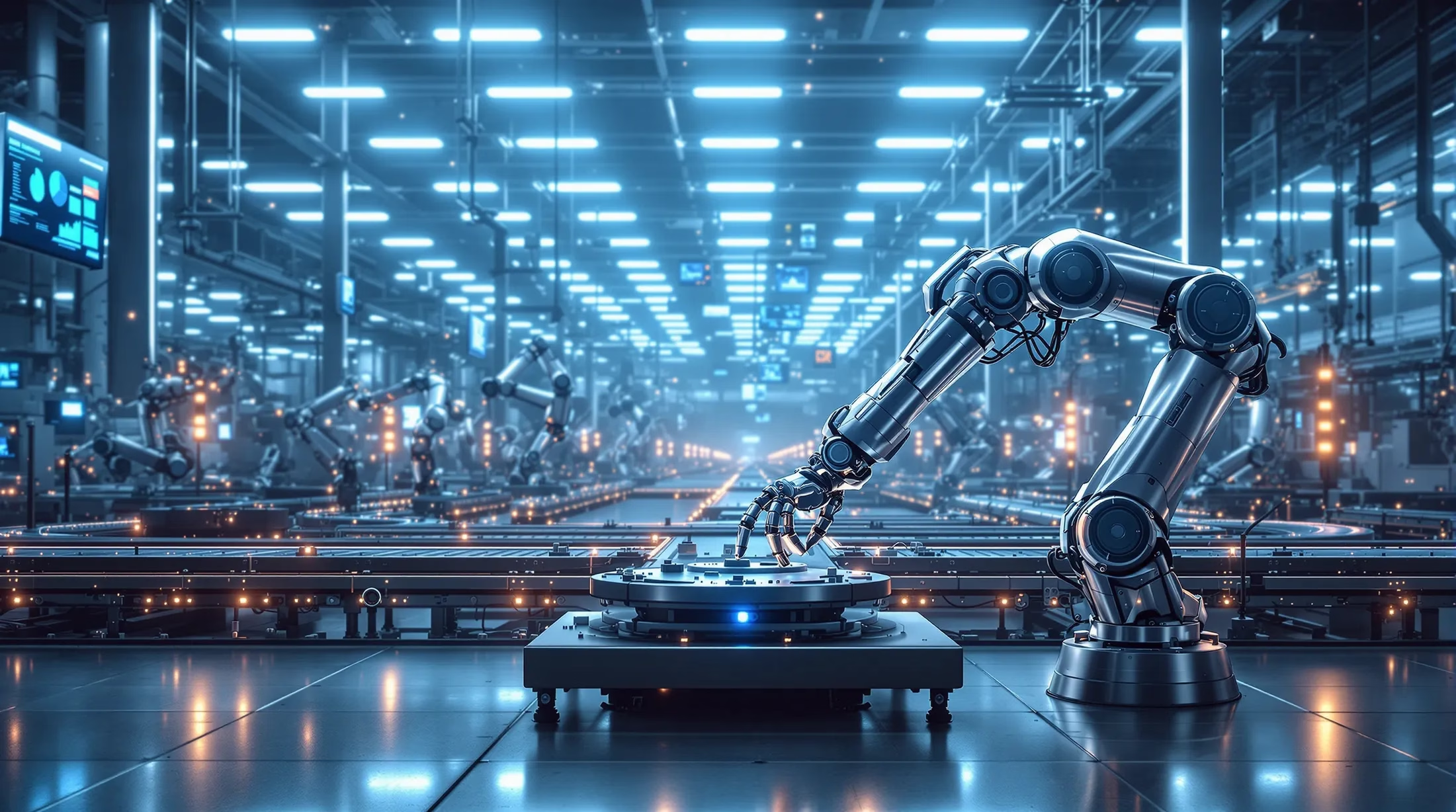

The manufacturing landscape is undergoing a remarkable transformation through robotic automation. From precision assembly to hazardous operations, industrial robots are reshaping production capabilities while setting new standards for efficiency and workplace safety. Let’s explore how these technological marvels are revolutionizing modern manufacturing.

Manufacturing robots have fundamentally transformed industrial processes through their unmatched precision and efficiency in automating repetitive tasks. These sophisticated machines now form the cornerstone of modern production lines, delivering significant advantages:

- Dramatic reduction in labor costs

- Enhanced output quality and consistency

- Improved workplace safety in hazardous environments

- Elimination of human error and fatigue-related issues

- Increased production throughput

What Are Manufacturing Robots?

Manufacturing robots are specialized automated machines engineered for specific industrial applications with minimal human oversight. These systems feature:

- Programmable mechanical arms with multi-axis mechanisms

- Advanced end effectors for specialized operations

- Sophisticated sensor and vision systems

- Intelligent control algorithms for environmental interaction

- Adaptable programming for various applications

History and Evolution of Industrial Robots

The industrial robotics journey began in the 1960s with Unimate’s deployment at General Motors. This milestone sparked rapid technological advancement, particularly in Europe during the 1970s. Key developments include:

| Period | Innovation | Impact |

|---|---|---|

| 1960s | Unimate’s Introduction | First commercial industrial robot deployment |

| 1973 | ABB’s IRB 6 | Pioneer in microprocessor-controlled electric robots |

| Present | Flexible Manufacturing Systems | Integration with PLCs for adaptable production |

Types of Manufacturing Robots

The manufacturing robot ecosystem encompasses various specialized systems, each optimized for specific industrial applications. These robots are categorized based on mechanical structure, freedom of movement, and intended use, enabling manufacturers to select the most suitable automation solution for their needs.

Articulated Robots and Their Applications

Articulated robots, the most versatile category in industrial automation, mirror human arm functionality with multiple rotary joints. Their capabilities include:

- Complex three-dimensional movement patterns

- Sophisticated obstacle navigation

- Multi-angle workpiece approach

- Precision in assembly line operations

- Versatility in welding and painting applications

- Advanced material handling capabilities

SCARA and Delta Robots: Speed and Precision

SCARA (Selective Compliance Assembly Robot Arm) robots excel in high-speed, precise lateral movements within a cylindrical work envelope. Their design features a rigid vertical axis combined with compliant horizontal axes, delivering exceptional accuracy in pick-and-place operations while minimizing floor space requirements. These specialized robots have become essential in manufacturing processes requiring:

- Rapid, repetitive movements in die-casting

- Precision handling in plastic injection molding

- Accurate placement in electronic component assembly

- Consistent positioning across production cycles

- Space-efficient automation solutions

Delta robots, featuring a parallel linkage design with three or four arms connected to a common base, achieve remarkable performance metrics:

| Feature | Capability |

|---|---|

| Speed | 300+ picks per minute |

| Primary Industries | Food and pharmaceutical packaging |

| Key Applications | High-speed sorting and placement |

Collaborative Robots: Working Alongside Humans

Collaborative robots (cobots) represent a revolutionary advancement in industrial automation, featuring built-in safety mechanisms that enable direct human-robot interaction. These systems incorporate:

- Advanced proximity sensors for human detection

- Force limitation technology for safe operation

- Rounded edges to prevent injuries

- Intuitive programming interfaces

- Hand-guiding capabilities for quick reprogramming

Leading manufacturers like Universal Robots, Techman Robot, and ABB have developed user-friendly collaborative platforms that transform traditional manufacturing environments. These systems excel in applications requiring both automated efficiency and human cognitive skills, creating flexible workstations where robots handle repetitive tasks while workers focus on complex decision-making and quality control. This synergy has proven particularly effective in maintaining high productivity while enabling workers to transition into higher-value roles supervising multiple cobots or managing process optimization.

Technological Advancements in Robotic Automation

Modern industrial robots now incorporate sophisticated digital interfaces and remote monitoring capabilities, fundamentally transforming manufacturing operations. These systems deliver significant competitive advantages through:

- Continuous operation without fatigue

- Consistent precision throughout production runs

- Advanced vision system integration

- Real-time analytics for decision-making

- Rapid adaptation to market demands

The Role of AI and Machine Learning

Artificial intelligence and machine learning are revolutionizing manufacturing robotics by creating systems that continuously learn and improve. These intelligent systems deliver substantial benefits:

- Predictive maintenance capabilities

- Autonomous error correction

- Enhanced quality control processes

- Optimized production scheduling

- Reduced waste and downtime

Industrial IoT and Data Analytics

Industrial Internet of Things (IoT) technology creates an interconnected manufacturing ecosystem where robots, sensors, and systems maintain constant communication. This integration enables:

- Real-time operational data collection

- Predictive maintenance scheduling

- Production bottleneck identification

- Automated performance optimization

- Energy consumption monitoring

- Waste reduction through precise control

Key Players in the Manufacturing Robots Market

The global manufacturing robots market features several industry pioneers who have shaped automation through continuous innovation. ABB, FANUC, and KUKA stand at the forefront, commanding substantial market share through their proven track records in delivering precision, durability, and exceptional return on investment across manufacturing sectors.

| Region | Leading Companies | Specialization |

|---|---|---|

| Japan | FANUC, Yaskawa Electric | Automotive manufacturing |

| Europe | ABB, KUKA | Electronics, pharmaceuticals, food processing |

Leading Companies and Their Innovations

ABB Robotics has revolutionized collaborative robotics with its YuMi series, creating the first true dual-arm collaborative robot for small parts assembly. Their FlexLoader vision software and OmniCore controllers have set new standards in robot performance and adaptability.

- FANUC’s distinctive yellow robots achieve 100,000+ hours of operation without failure

- KUKA’s orange KR QUANTEC series offers unmatched payload capacity with precision

- Yaskawa Electric’s Motoman excels in specialized arc welding applications

- Comau’s blue robots dominate European automotive assembly lines

- Each manufacturer invests heavily in AI capabilities and simplified programming interfaces

Challenges and Future of Manufacturing Robots

The manufacturing robotics sector faces several critical obstacles while continuing its rapid evolution. Integration complexity, high initial investments, and technical compatibility issues present significant challenges, particularly for small and medium-sized enterprises.

- AI and machine vision advancements driving next-generation capabilities

- Development of adaptive robots requiring minimal reprogramming

- Enhanced object recognition and manipulation abilities

- Improved human-robot collaboration in dynamic environments

- Democratization of access to robotic automation technology

Overcoming Integration and Cost Barriers

Integration challenges primarily stem from legacy equipment compatibility issues and the need for extensive production line reconfiguration. Modern solutions include:

- Modular automation approaches for gradual implementation

- Robot-as-a-Service (RaaS) subscription models

- Simplified programming interfaces reducing specialist requirements

- Decreasing hardware costs improving accessibility

- Custom integration solutions for legacy systems

The Future Role of Humans in Automated Industries

The relationship between human workers and automated systems is undergoing a fundamental transformation in manufacturing careers. Evidence suggests that rather than causing widespread job displacement, automation is creating a shift in required human competencies. The manufacturing workforce of tomorrow will need to develop expertise in:

- Robot operation and programming

- System maintenance and troubleshooting

- Performance optimization and analysis

- Critical decision-making

- Data interpretation and management

Human cognitive abilities remain irreplaceable in automated environments, particularly in areas where robots show limitations:

| Human Strengths | Robot Strengths |

|---|---|

| Abstract thinking | Predictable, repetitive tasks |

| Creative problem-solving | Precision and consistency |

| Adaptation to unexpected situations | Physical endurance |

| Strategic oversight | High-speed operations |

The most successful manufacturing operations will be those that strategically divide responsibilities between humans and robots, leveraging each for their unique capabilities. This symbiotic relationship creates manufacturing environments that are simultaneously more productive and engaging for human workers, whose roles evolve from manual operators to technology managers focused on continuous improvement and system optimization. To facilitate this transition, significant investments in workforce development and training programs will be essential for employee adaptation to these new responsibilities.