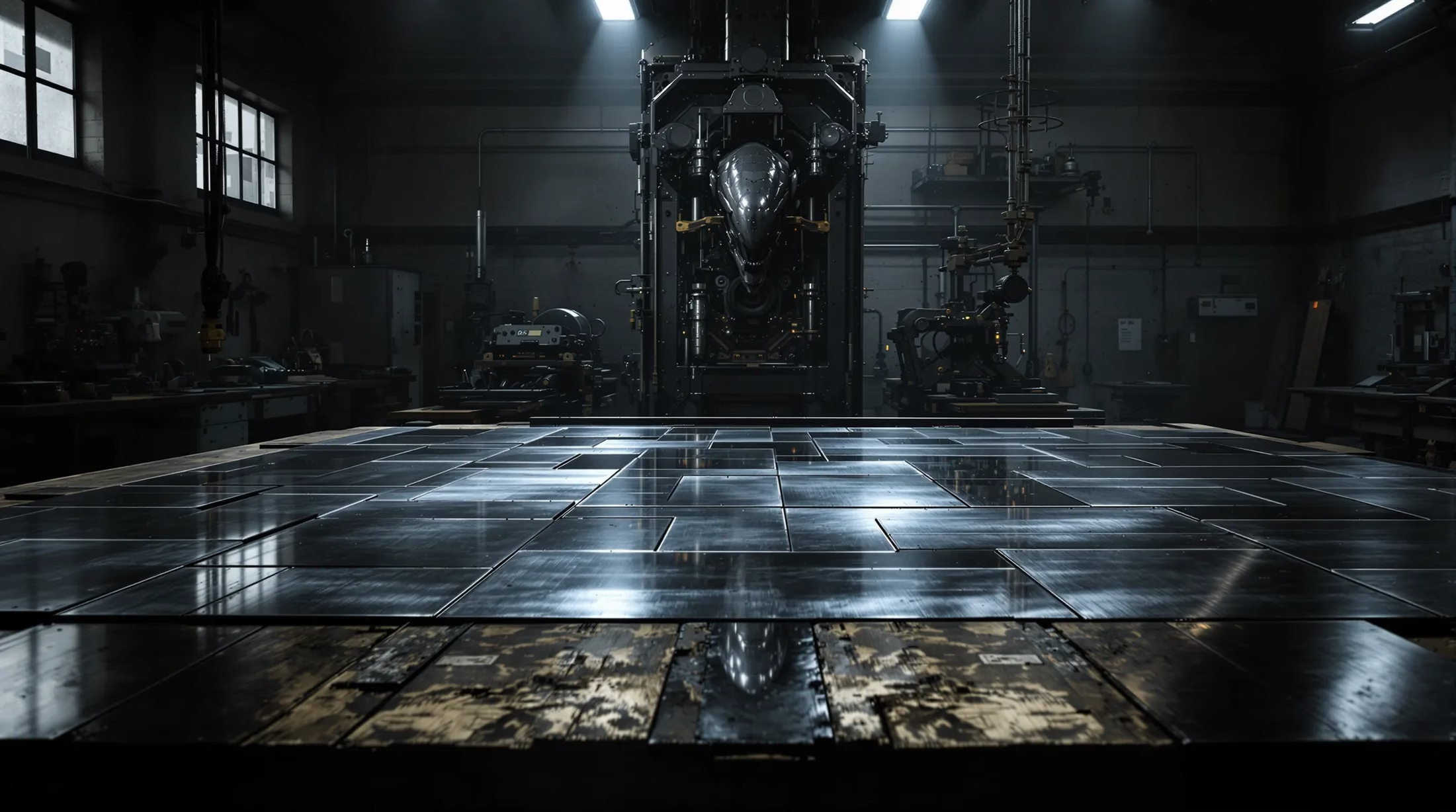

Sheet Metal Fabrication: Techniques, Benefits, and Applications

Discover the transformative world of sheet metal fabrication, where raw metal sheets become sophisticated components through precision engineering and artistic craftsmanship. This comprehensive guide explores the evolution, techniques, and applications of this vital manufacturing process that shapes modern industry.

Understanding Sheet Metal Fabrication

Sheet metal fabrication combines artistic craftsmanship with engineering precision to transform flat metal sheets into functional components. Modern fabrication techniques have revolutionized the industry through advanced technology, including CNC machines, laser cutting, and automated systems that deliver unprecedented precision while reducing production time.

What is Sheet Metal Fabrication?

Sheet metal fabrication transforms flat metal sheets into three-dimensional products through a series of precise operations. The process utilizes metal sheets ranging from 0.006 to 0.250 inches in thickness and encompasses various metals including:

- Steel

- Aluminum

- Brass

- Copper

- Titanium

- Tin

The fabrication process follows a systematic approach:

- Design and engineering planning

- Cutting metal sheets to specifications

- Forming through bending, rolling, or stamping

- Assembly via welding, riveting, or fastening

History and Evolution of Sheet Metal Fabrication

The journey of sheet metal fabrication spans millennia, beginning with ancient civilizations in Mesopotamia, Egypt, and China around 5000 BCE. These early metalworkers developed fundamental techniques for hammering metals into thin sheets, laying the groundwork for modern fabrication.

| Era | Key Developments |

|---|---|

| Ancient Times | Manual hammering techniques, basic metalworking |

| Middle Ages | Refined blacksmith methods, specialized tools |

| Industrial Revolution | Power-driven equipment, mechanized processes |

| Modern Era | CAD/CAM software, laser cutting, robotic systems |

Techniques in Sheet Metal Fabrication

Modern sheet metal fabrication employs sophisticated manufacturing processes that combine traditional expertise with cutting-edge technology. Computer-controlled systems ensure consistent production while maintaining precise tolerances across various applications.

Cutting Techniques

Contemporary fabrication relies on several advanced cutting methods:

- Laser Cutting – Offers exceptional precision and clean edges

- Plasma Cutting – Ideal for thick materials using ionized gas

- Waterjet Cutting – Perfect for heat-sensitive materials

- Traditional Punching – Cost-effective for high-volume production

- Shearing – Efficient for straight-line cuts

Bending and Forming

Press brakes serve as the foundation of modern bending operations, utilizing hydraulic or electric power to create precise angles between punch and die components. These advanced machines feature CNC-controlled backgauges with hard stops for exact part positioning and bend line placement, ensuring consistent results across production runs.

- Air bending – creates angles through partial die contact

- Coining – applies greater force for complete die shape conformity

- Roll forming – gradually bends metal through sequential rollers

- Stamping – creates forms through single-press operations

- Deep drawing – stretches metal over forms for 3D shapes

- Hydroforming – uses hydraulic pressure for complex geometries

Joining Methods

The assembly phase encompasses various techniques for connecting sheet metal components into unified structures. Welding remains the predominant method, with several specialized processes:

- MIG (Metal Inert Gas) welding – versatile for various materials

- TIG (Tungsten Inert Gas) welding – precise control for detailed work

- Spot welding – efficient for overlapping joints

- Robotic welding – automated precision for high-volume production

- Riveting – ideal for joining dissimilar metals

- Threaded fasteners – enable component disassembly

- Crimping and seaming – fastener-free edge joining

- Adhesive bonding – distributes stress evenly without heat distortion

Benefits of Sheet Metal Fabrication

Sheet metal fabrication transforms flat metal sheets into functional components with exceptional precision and efficiency. Modern techniques have enhanced these capabilities, enabling complex designs while maintaining cost-effectiveness. The integration of advanced technology with traditional expertise positions sheet metal fabrication as an essential manufacturing process, offering strategic advantages throughout the product development cycle.

Durability and Strength

Sheet metal components deliver exceptional structural integrity through various enhancement techniques:

- Work hardening during bending increases tensile strength

- Reinforcement ribbing provides additional structural support

- Strategic bending optimizes load distribution

- Material thickness optimization balances strength and weight

- Natural resistance to environmental factors (UV, temperature, moisture)

Cost-Effectiveness

| Benefit | Impact |

|---|---|

| Material Optimization | 80%+ utilization through advanced nesting software |

| Setup Efficiency | Quick changeover for both prototypes and production |

| Operational Costs | Reduced replacement frequency and shipping costs |

| Design Flexibility | Cost-effective modifications without extensive retooling |

Versatility and Customization

Sheet metal fabrication stands out through its exceptional versatility across materials and techniques. Fabricators work with an extensive range of metals, including:

- Steel – for structural strength and durability

- Aluminum – lightweight yet robust

- Copper – excellent electrical conductivity and corrosion resistance

- Specialized alloys – for specific performance requirements

Custom sheet metal fabrication leverages modern CAD/CAM systems for rapid prototyping and design iterations. This technology-driven approach enables precise component creation across various production scales, from small prototype runs to high-volume manufacturing. The customization possibilities extend through multiple finishing techniques:

- Perforating for ventilation and aesthetic appeal

- Embossing for structural reinforcement

- Powder coating for durability and color options

- Plating for enhanced surface properties

- Anodizing for corrosion resistance

Applications of Sheet Metal Fabrication

Sheet metal fabrication has become indispensable across numerous industries through its unique combination of precision, strength, and adaptability. Advanced CNC technology and computer-aided design have expanded manufacturing capabilities, enabling the creation of increasingly complex components with exceptional accuracy. This evolution serves diverse sectors including manufacturing, construction, and transportation.

Automotive Industry

| Component Type | Application |

|---|---|

| Body Panels | External vehicle structure and aesthetics |

| Chassis Components | Structural integrity and safety |

| Battery Enclosures | Protection for electric vehicle systems |

| Custom Parts | Specialty vehicles and motorsport applications |

Construction and Architecture

The construction sector utilizes sheet metal fabrication for both structural and aesthetic elements. Key applications include:

- Steel framing systems for building support

- Custom facades and decorative panels

- Integrated roof systems and ductwork

- Rain screens and sun shades for energy efficiency

- Architectural accents and ornamental features

Electronics and Appliances

In electronics manufacturing, sheet metal fabrication provides crucial solutions for component protection and thermal management. Applications include:

- EMI/RFI shielding enclosures

- Server racks and equipment chassis

- Appliance exteriors and structural components

- Heat dissipation systems

- Precision-engineered housings

Materials Used in Sheet Metal Fabrication

Sheet metal fabrication encompasses a diverse range of materials, each offering distinct properties for specific applications. The transformation of flat metal sheets into functional components occurs through precise cutting, bending, and forming operations. Material selection significantly influences the final product’s performance characteristics, including strength, weight, and corrosion resistance.

Common Metals Used

| Material Type | Properties and Applications |

|---|---|

| Mild Steel | Excellent formability, weldability, economical choice |

| Stainless Steel (304, 316) | Superior corrosion resistance, ideal for harsh environments |

| Galvanized Steel | Zinc-coated protection, weather-resistant for outdoor use |

| Aluminum (5052, 6061) | Lightweight, corrosion-resistant, high thermal conductivity |

| Copper and Alloys | Excellent electrical conductivity, antimicrobial properties |

Material Selection Criteria

- Mechanical Properties – tensile strength, yield strength, hardness, and fatigue resistance

- Environmental Factors – resistance to moisture, chemicals, salt spray, and temperature extremes

- Manufacturing Considerations – machinability, formability, and weldability

- Cost Factors – material pricing, availability, processing requirements, and lifespan

- Weight Requirements – particularly crucial for transportation applications

- Regulatory Compliance – specific requirements for food processing, medical, and aerospace applications

- Aesthetic Requirements – surface finish, color options, and texture possibilities

Tools and Equipment in Sheet Metal Fabrication

Modern fabrication facilities combine traditional metalworking tools with advanced technology to achieve precise results. The integration of computer numerical control (CNC) systems has revolutionized the industry, enabling programmed operations with consistent accuracy and minimal human intervention.

Cutting Tools

- Industrial Shears – clean, straight cuts for high-volume production

- Band Saws – precision cuts through various metal thicknesses

- Laser Cutters – intricate patterns with minimal material distortion

- Plasma Cutters – efficient cutting for conductive materials

- Water Jet Systems – versatile cutting without heat affected zones

- Portable Power Tools – on-site adjustments and finishing work

Forming Equipment

Press brakes and sheet metal rollers serve as fundamental tools in transforming flat metal sheets into three-dimensional components. Modern CNC press brakes deliver exceptional accuracy through programmable back gauges and multi-axis control systems, ensuring consistent bending along pre-determined lines. Sheet metal rollers excel at creating cylindrical components by guiding metal between adjustable rollers, enabling the production of everything from simple tubes to complex conical sections.

- Press Tools and Dies – specialized tooling for specific forming operations, from V-bends to complex hemming

- Stamping Presses – enable rapid production through consistent pressure application

- Stretch Forming Equipment – creates compound curves for aerodynamic shapes

- English Wheels – manual forming tool for custom curved surfaces

- Shrinking/Stretching Machines – specialized equipment for complex contours

Joining Tools

| Welding Type | Characteristics and Applications |

|---|---|

| MIG (Metal Inert Gas) | High-speed deposition, ideal for structural joints |

| TIG (Tungsten Inert Gas) | Exceptional precision for visible or critical connections |

| Spot Welding | Rapid, consistent joints in overlapping sheets |

Beyond welding, mechanical fastening tools provide alternative joining methods without heat application. These include rivet guns, clinching tools, and specialized thread-forming equipment. For temporary or adjustable connections, fabricators employ installation tools for nuts, bolts, and self-clinching fasteners, allowing optimal connection selection based on structural requirements and aesthetic considerations.

Choosing a Sheet Metal Fabrication Service

Success in sheet metal fabrication projects heavily depends on selecting the right service provider. Modern fabricators offer varying capabilities, from specialized operations to comprehensive end-to-end solutions including design, production, and assembly. Advanced technologies such as laser cutting, CNC machinery, and automated systems enhance precision while reducing lead times.

Factors to Consider

- Technical Capabilities – equipment compatibility with project requirements

- Quality Management – certification standards and quality control processes

- Production Capacity – ability to handle required volumes

- Industry Experience – expertise in relevant sectors

- Financial Stability – investment in technology and long-term reliability

- Communication Practices – responsiveness and service level indicators

Questions to Ask

- Service Range – comprehensive solutions vs. specialized processes

- Production Timeline – typical lead times for prototypes and production runs

- Material Management – sourcing practices and inventory policies

- Quality Control – inspection procedures and tolerance management

- Problem Resolution – approach to handling unexpected challenges

- Project Communication – update protocols and technical consultation availability

- Design Support – capabilities for design assistance and optimization